HIGHEST STANDARDS CALL FOR PERFECT INSULATION PROBERTIES

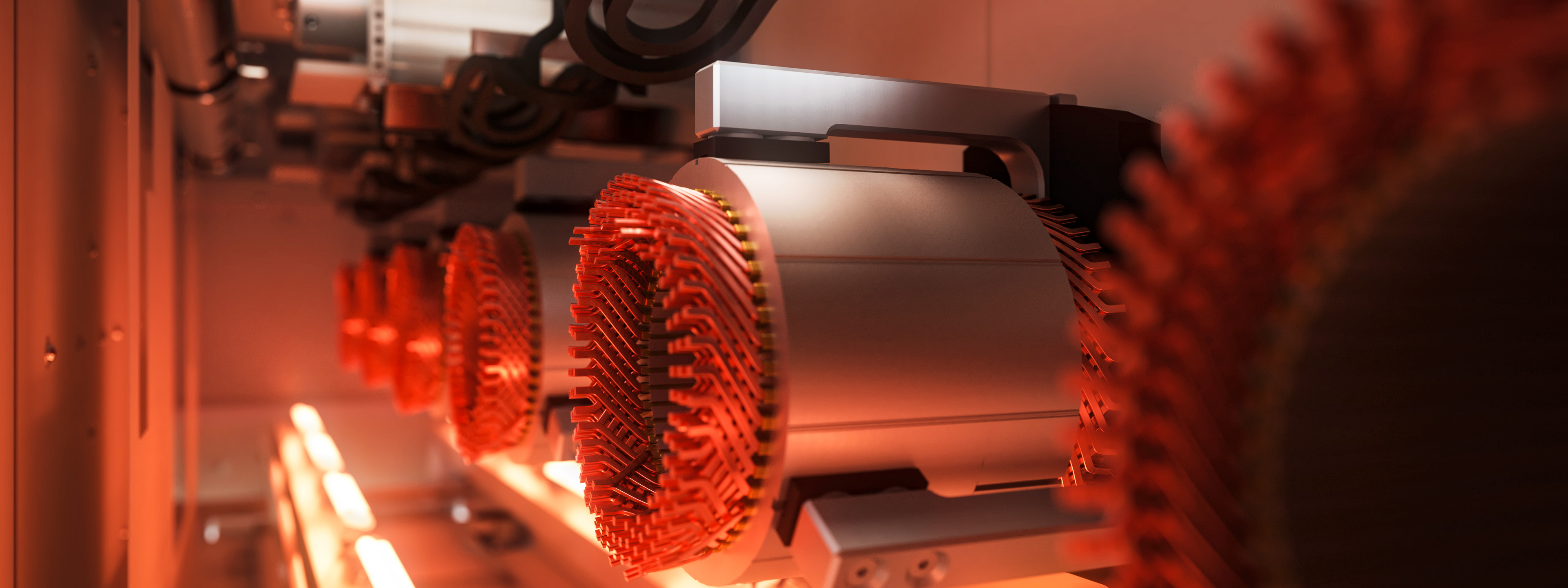

Because of the high performance density of electric motors for automobile manufacturing, a faultless insulation of the invididual components is decisive for their production. Furthermore, these motors have to withstand high physical exposures. Modern high-performance traction motors often revolve at more than 20,000 rpm.

The heart of an electric motor consists of the stator and a rotor. Depending on the type of construction, various methods are used for insulation – impregnation or casting of the motor components under vacuum. HEDRICH can offer equipment designs for both processes.

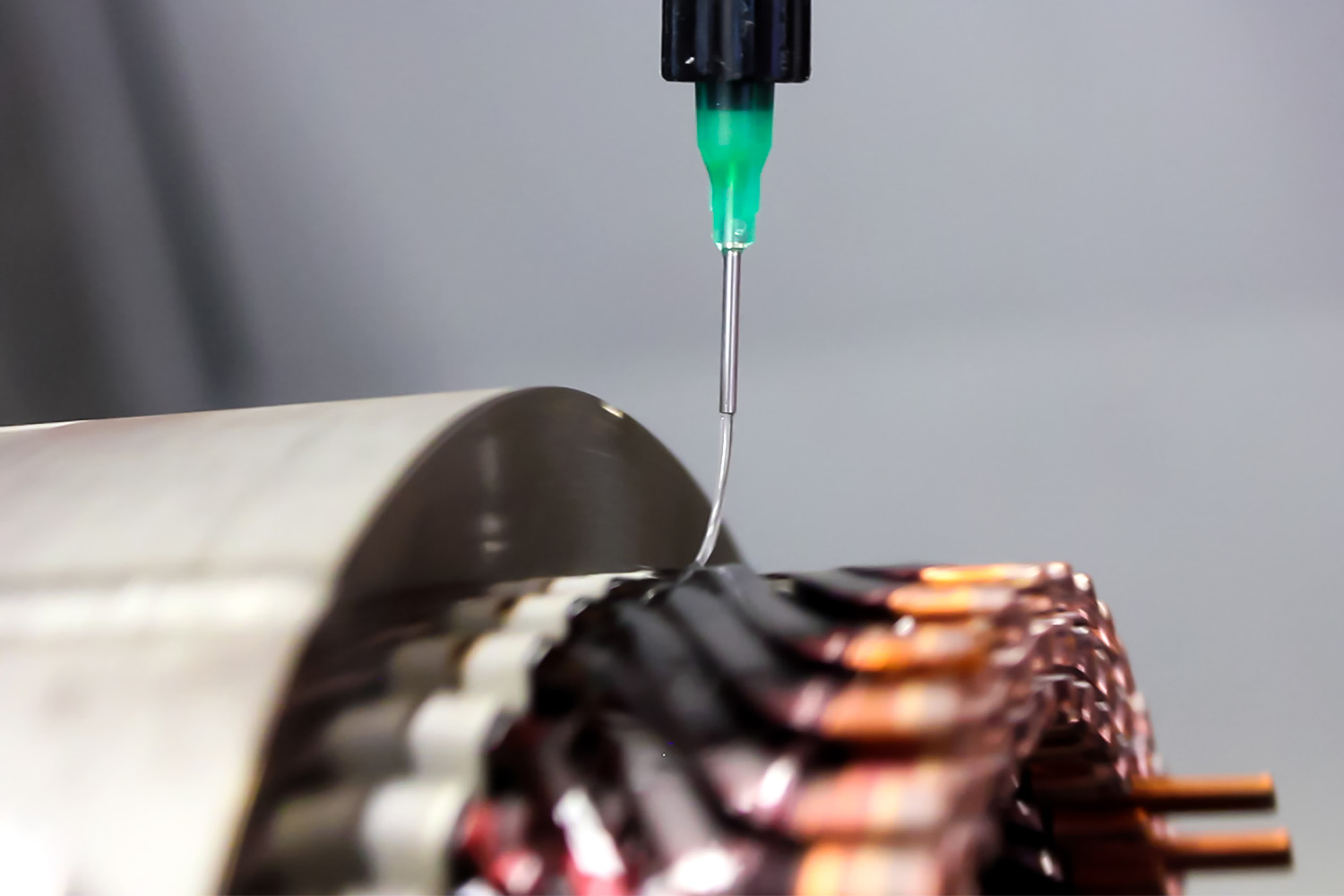

Impregnation

- Trickling

- Immersion (under atmosphere or vacuum)

- Plunge-rolling

- UV hardening

- Hot impregnation

- Vacuum pressure impregnation (VPI)

Casting

- Vacuum casting/APG of stators and rotors

Appropriate equipment is available designed both as stand-alone units or within the scope of complete production lines. In this case, HEDRICH will supply the complete package of equipment and process technology, comprising casting and impregnation equipment, oven technics, handling systems and superior process control.

For possibly requested pre-tests or prototype manufacturing, HEDRICH can provide their optimally equipped testing laboratory with experienced process specialists.

Automotive:

Protection for Sensors/Electronics in „Sophisticated” Environment

The permanent optimization of convenience, efficiency and safety has placed the requirements to measuring and control systems for car manufacturing on a high level – and they are going to rise further rapidly when it comes to the subject of „autonomous driving". Besides, highly sensitive components like sensors, electronics and ignition coils are partially exposed to extreme conditions: ambient temperatures of -40 to +60 degrees are not unusual – temperatures of even up to 180 degrees Celsius can be found in the range of the motor and powertrain. Encapsulation of the components under vacuum provides safe protection and allows resistance to partial discharge for high-voltage applications such as ignition coils in the range of 35 kV. In the field of electric drives, HEDRICH is one of the leading suppliers for the va-cuum-based manufacturing of insulations for stators and rotors. Also covered by the HEDRICH portfolio: the casting of battery modules and power electronics.

Customer Benefit

Customer Benefit

Customer Benefit

Customer Benefit