Innovations

Innovations

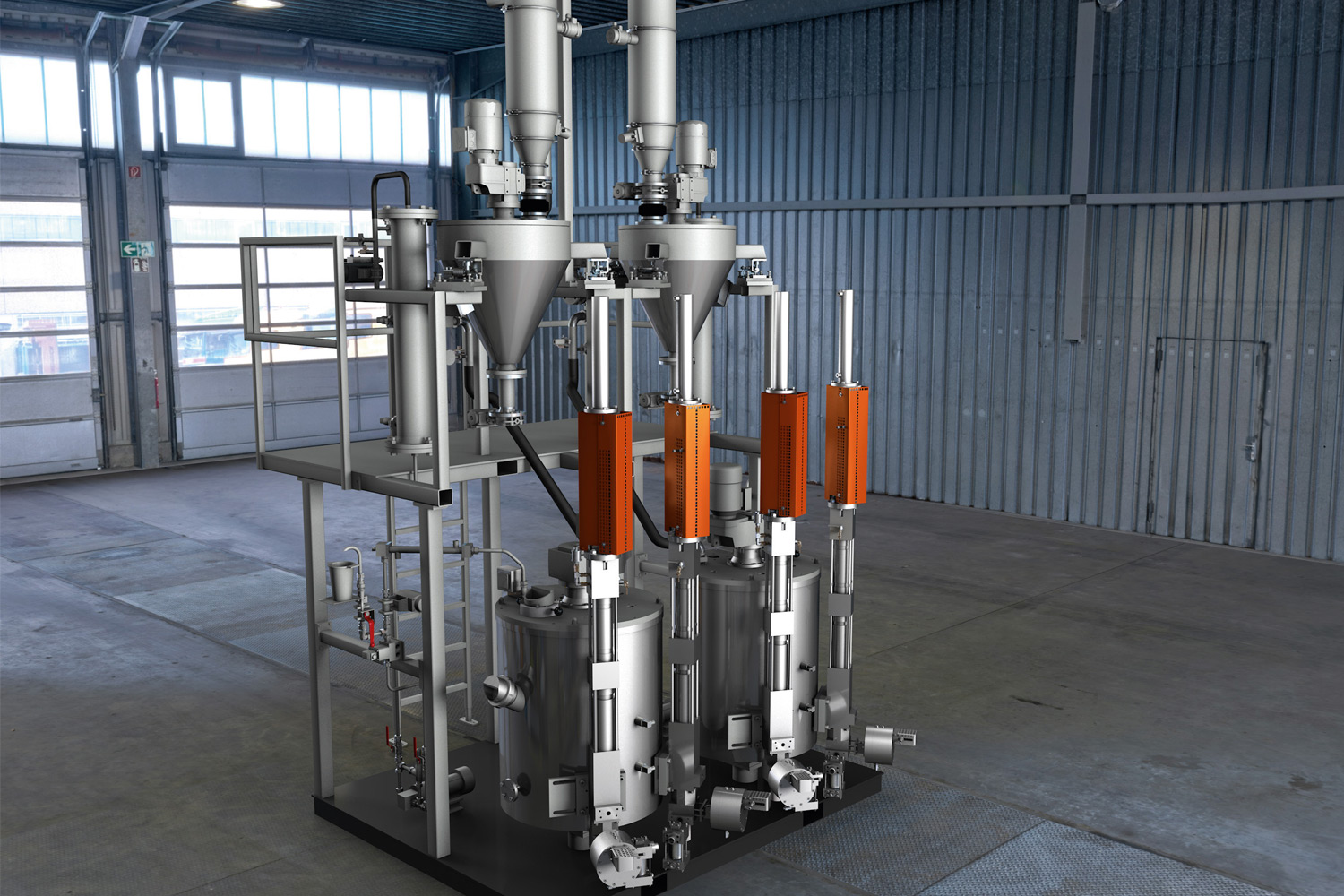

You want to know more about our vacuum casting equipment with MTB technology, smart applications to autonomously control the equipment and mobile real time monitoring as implied by the Industry 4.0 or just intelligent equipment designs? – Then you are right here to gain an outline on our entire variety of innovations implemented over the recent years.