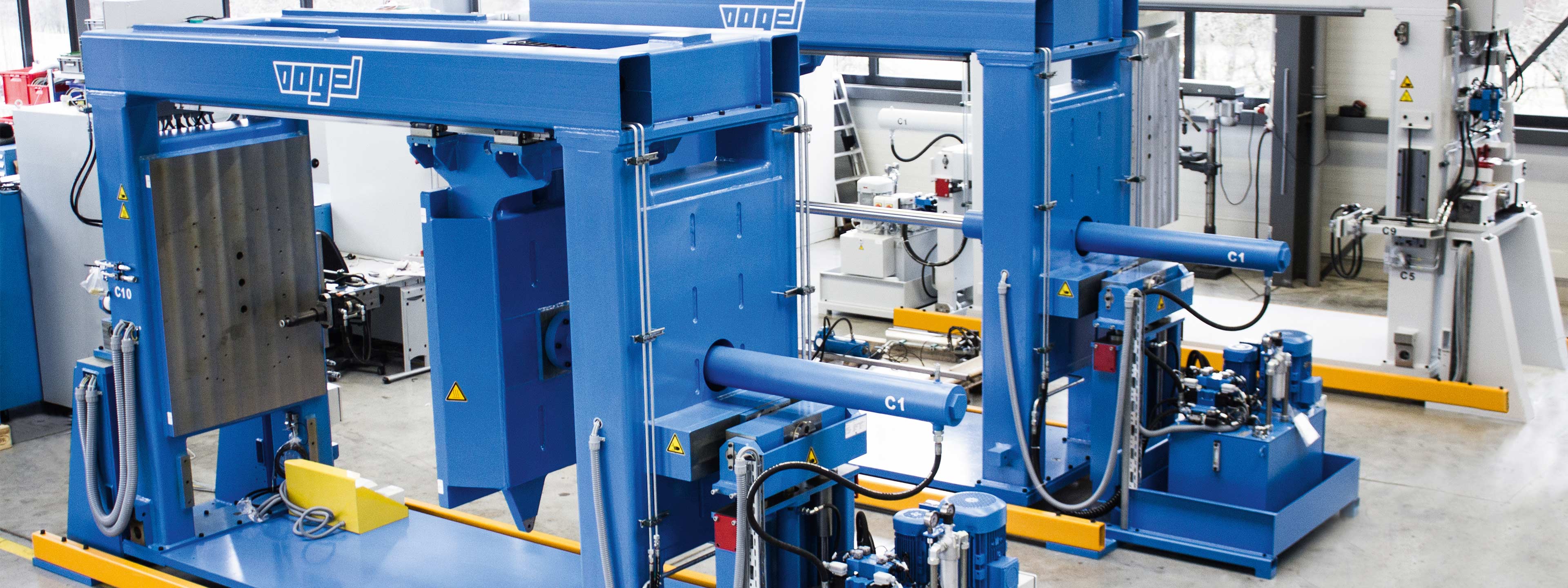

APG Clamping Units: Reliable, Sturdy and Long-Lasting

All VOGEL APG clamping units are manufactured with great care and in accordance with the latest technical findings. The systems are reliable, extremely sturdy and long-lasting. The versatile and sophisticated functionality as well as expandability of the machines founds the ideal basis to also meet all future requirements as well as production methods growing more and more complex and fast.

|

|

Modular Extendable |

The modular arrangement of the clamping units for the automatic pressure gelation allows to adapt the equipment exactly to the customer’s needs. For example, the core pullers (top, bottom, lateral) and the tilting of the machine around one or two axes can be integrated as option or installed later. It is also possible to provide the unit with a quick-clamp system for fast and easy mould change.

|

|

Stable and Precise |

All systems are provided with a very sturdy and warp resistant machine frame, which is optimized for the occurring changes in load. The massive moving carriage suspends from precision guidances, ensuring absolute parallel closing as well as clean and smooth opening of the sensitive clamped casting moulds.

|

|

Versatile and Intuitive |

Thanks to the modern and intuitive control, just one click is necessary to change the screen and edit parameters quickly. Functions like cylinder positions, heating parameters (temperatures and PID values) and hydraulic pressure are clearly visible. All process-relevant steps can be selected from a library and stored as program along with the other parameters.

|

|

Minimum Service Required |

The simple and modern mechanical machine arrangement minimizes the necessity for maintenance and repair. No components are used that are subject to excessive wear. Therefore, the down times per year as well as costs arising for maintenance and service are very low.

Advantages of APG Clamping Units

Advantages of APG Clamping Units

• Highest stability, precision and long service life

• Best accessibility from both sides

• Clear intuitive control

• Special equipment as vacuum chamber, slide, quick-clamp system

• All components made by renowned manufacturers – worldwide availability of spare parts

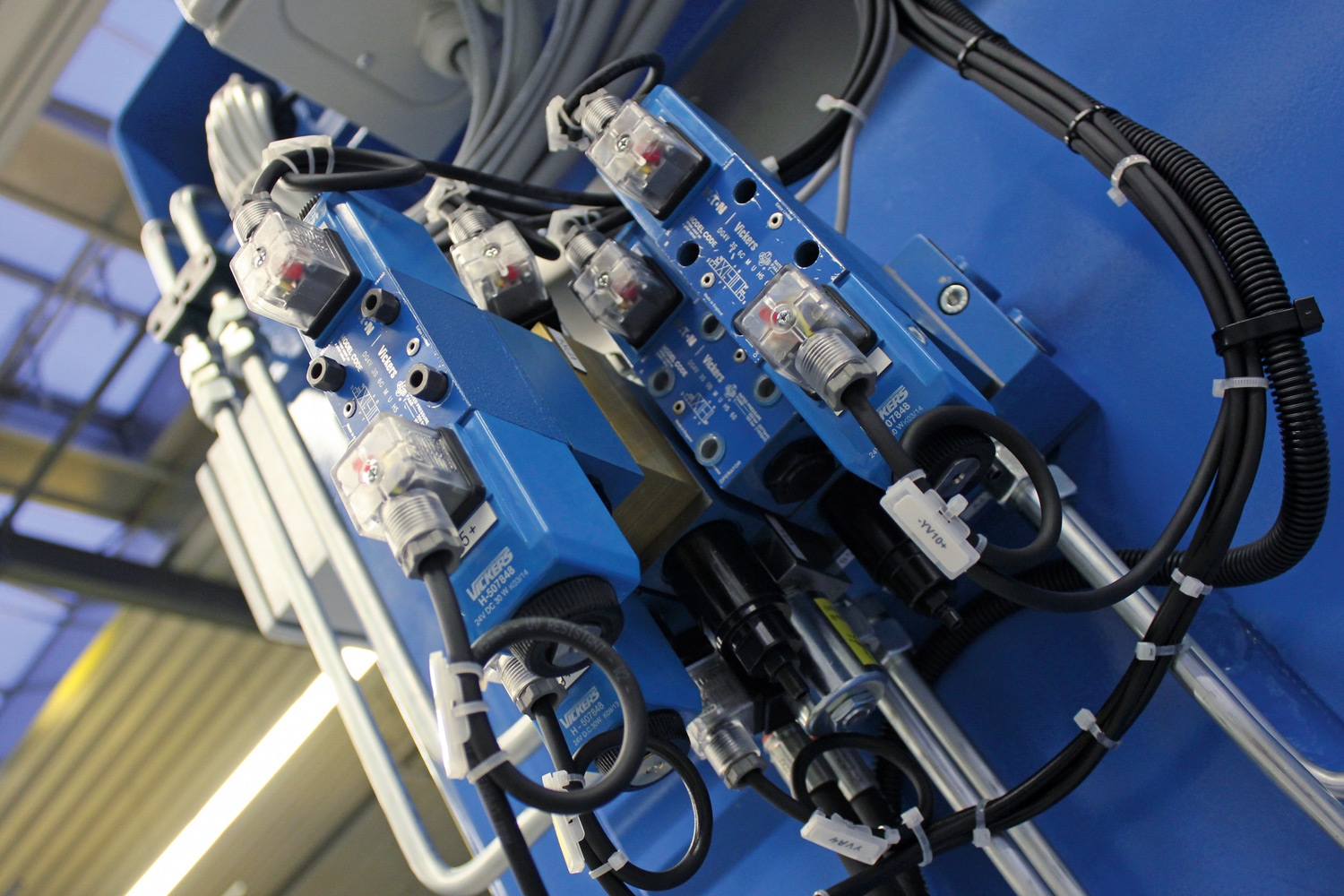

• Fixed, inside-arranged piping and wiring as well as attached hydraulics

• Easy and fast setting-up as well as start-up

• Positioning of all axes via linear encoder systems

• Free programming directly in the control

Applications

Applications

• Switch housings with and without integrated vacuum tube

• Bushings of al kinds

• Insulating parts for medium and high voltage switch gears

• Switching rods

• Insulating tubes