Equipment for the Drying and Impregnation of Cables

Our cable impregnation systems are designed to dry and impregnate signal and HV/HVDC energy cables according to customer requirements. Based on 45 years of experience and more than 35 delivered cable impregnation systems, our comprehensive quality assurance management provides highest standards of quality, efficiency and reliability.

|

|

Guaranteed Reliability |

During the past 10 years we could obtain a process reliability going far beyond the standard requirements and guarantee downtimes of a few hours only with process times of more than 40 days.

|

|

Purification in One Pass |

The special filtering devices, feeder pumps and valves as well as the 2-stage HEDRICH thin-film de-gasser are exactly designed for the cable compound to be used. Highest purification qualities and optimum dielectric and mechanical properties are thus guaranteed already after one pass.

|

|

Effective Drying |

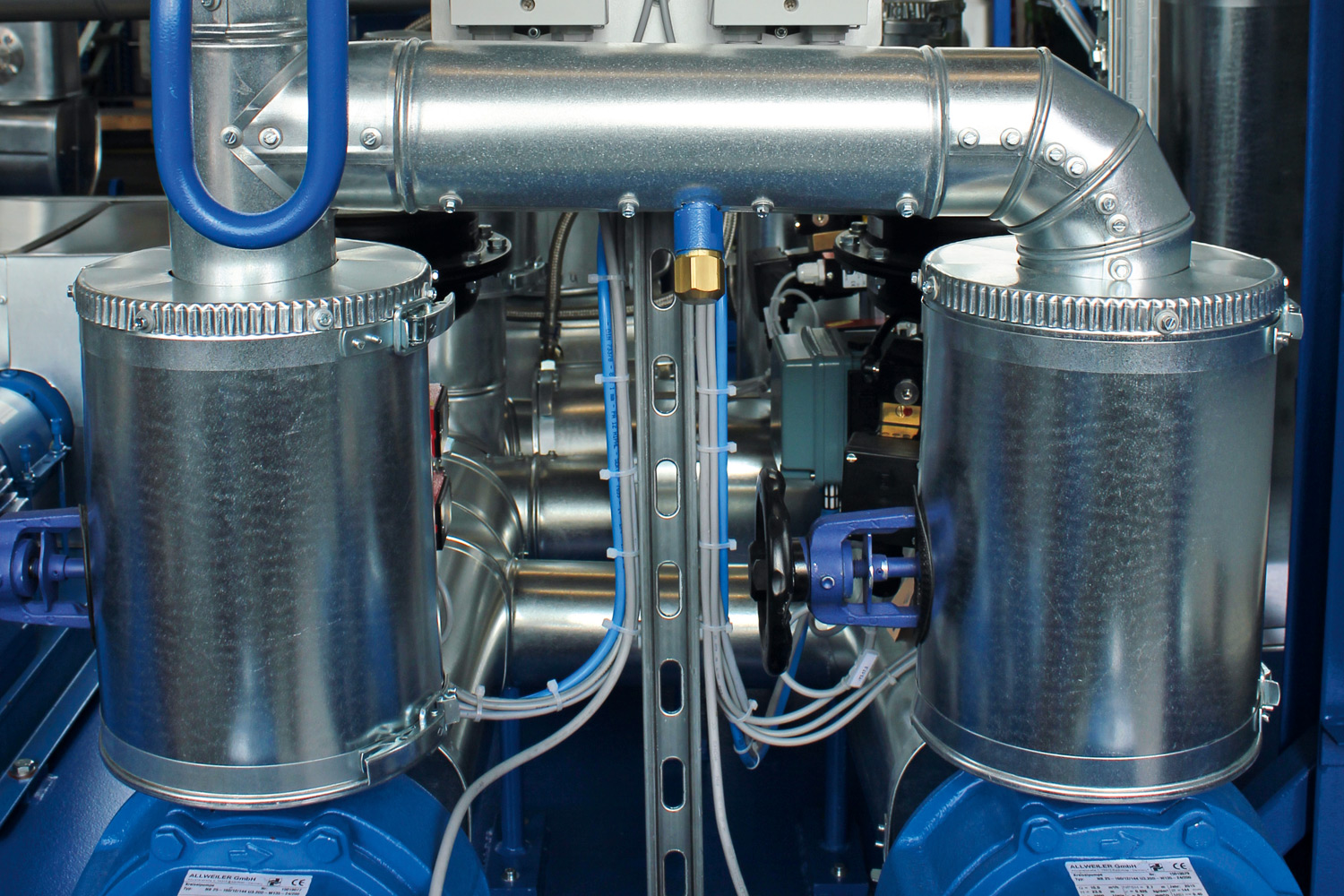

The extremely sturdy and reliable vacuum pumping units with a pumping speed of up to 30,000 m3/h and low ultimate vacuum in the range of 10-4 mbar are provided with special condensers and exhaust devices to effectively pump out the high quantities of water vapour emanating during the vacuum drying.

|

|

Clean Impregnation |

In case cable compound emanates, it is collected separately in special condensers and is pumped out without affecting the vacuum pump capacity. The pipes of the nearly maintenance-free, dry-running screw vacuum pumps are easily cleaned by means of a spray device.

Advantages of vacuum cable impregnation systems:

Advantages of vacuum cable impregnation systems:

• 2-stage special thin-film degasser to degas and dehumidify highly viscous cable compound

• Temperature-controlled storage of the cable compound under vacuum up to 550 m³

• Use of proven feeder pumps for careful transport

• Use of safety heat exchanger

• Design of pipelines to convey cable compound with trace heating

• Impregnation systems for rotatable tank sizes up to 700 m³

• Controlled and recorded compliance of the heating and cooling phases

• Special condensers and exhaust devices for high water vapour quantities

• Automatic levelling of the filling level and control of the impregnation pressure

• 4-stage vacuum pumping units up to 30,000 m³/h; ultimate vacuum up to 10-4 mbar

• Easy cleaning of compound containing equipment parts

• Spray device to clean screw vacuum pumps

Applications

Applications

• Oil/paper-insulated special cable

• Purification of cable oil and cable compound