HEDRICH offers a variety of drying technologies for different applications. Only carefully dried insulation materials ensure a trouble-free operation of electric high-performance components and slow down the aging process. For the materials used to insulate transformers it is extremely important to minimize moisture to guarantee dielectric strength and dimensional stability.

- Search

-

Industries

- Industries

- Electrical (Grid)

- Electronic (Potting)

- Wind

- Other

-

Products

- Products

-

Technologies

- Technologies

- Equipment for Cast Resin Insulation

-

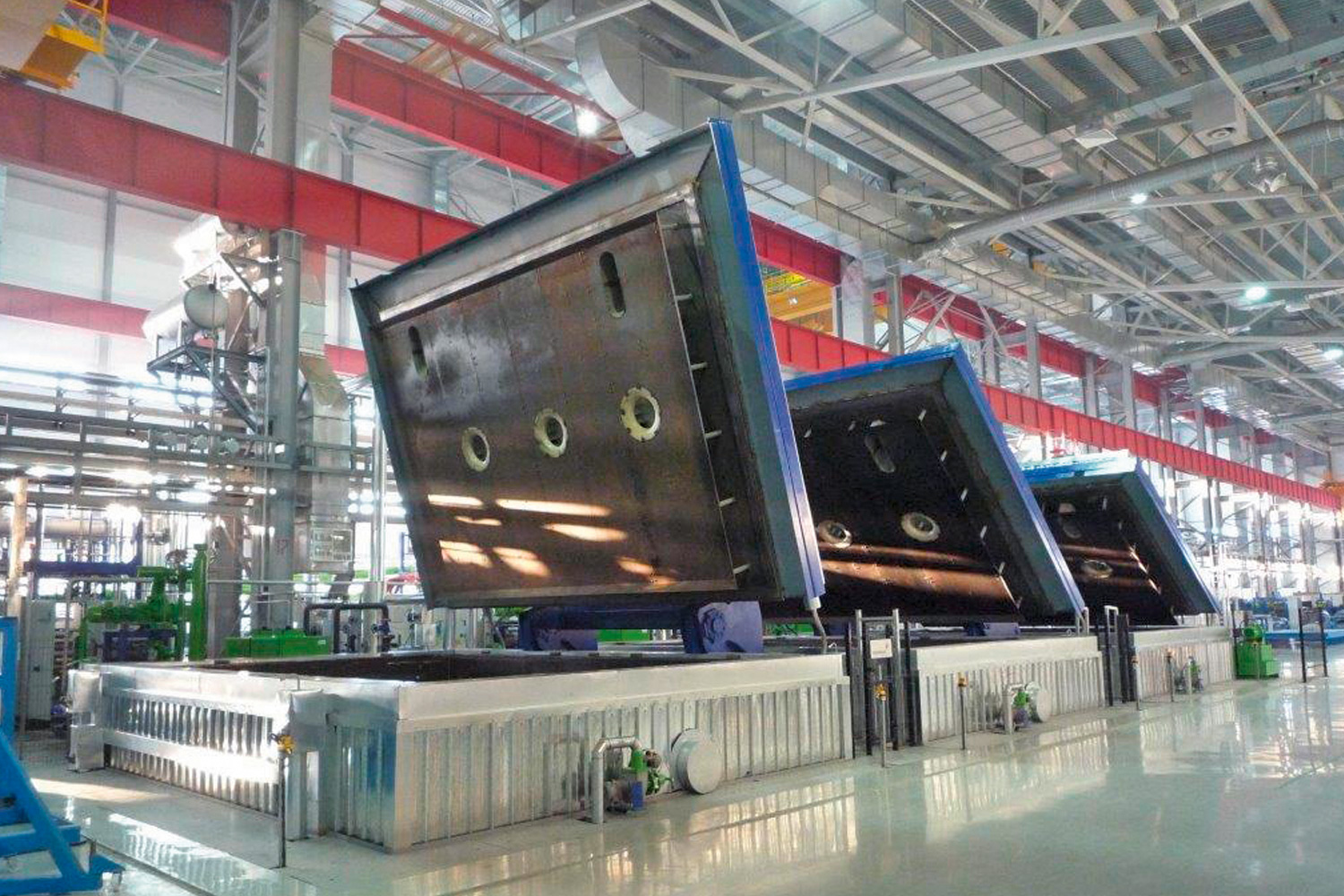

Equipment for Oil/Paper Drying and Stabilization

- Equipment for Oil/Paper Drying and Stabilization

- Vacuum Hot Air Drying Equipment

- Vacuum Nitrogen Drying equipment

-

Low-Frequency Drying Equipment

- Low-Frequency Drying Equipment

- Low-Frequency Drying Equipment

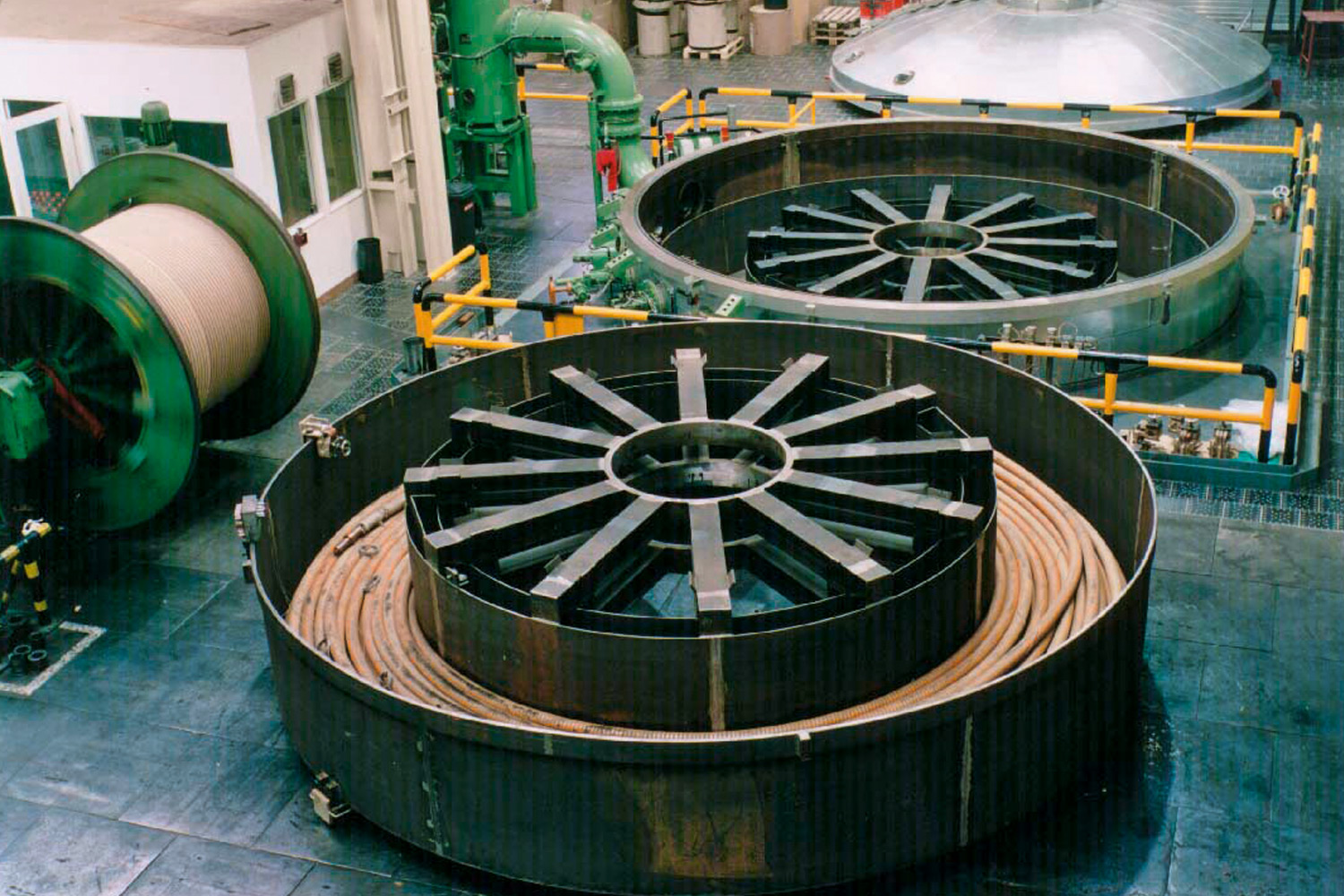

- The New Generation of Vapour Phase Equipment

- Vacuum Drying and Impregnating Equipment

- Vacuum Oil Purification Equipment

- Vacuum Cable Impregnation Equipment

- Isostatic Presses

-

Clamping Machines, Moulds, APG, Mixing and Dosing Systems

- Clamping Machines, Moulds, APG, Mixing and Dosing Systems

-

Clamping Units

- Clamping Units

- APG Clamping Units

- LSR Clamping Units

- Moulds for APG and LSR

-

LSR Mixing and Dosing Systems

- LSR Mixing and Dosing Systems

- Type DosilOne Advanced

- Type DoskoSil

- Special Equipment and Automation Solutions

- Equipment for Vacuum Pressure Impregnation (VPI)

- Vacuum Pumping Units

-

Innovations

- Innovations

- Innovation Timeline

-

Innovations

- Innovations

- Mobile Low-Frequency Drying Equipment

- Material Suppliers

- Service

-

Company

- Company

-

Philosophy

- Philosophy

- Mission Statement

- Guidelines & Values

- Code of Conduct

-

About HEDRICH

- About HEDRICH

- HEDRICH GROUP

- More than just products

-

TOP EXPERT

- TOP EXPERT

- EFFICIENCY

- QUALITY

-

HEDRICH International

- HEDRICH International

- HEDRICH China

- VOGEL

- HEDRICH INDIA

- HEDRICH North America

- Sales Agents and Representatives

-

HEDRICH 4.0

- HEDRICH 4.0

- Smart Products

- Smart Processes

- Smart Factory

-

News

- News

- Web-News

-

Fairs, Exhibitions and Events

- Fairs, Exhibitions and Events

- Dates

- Impressions from Fairs