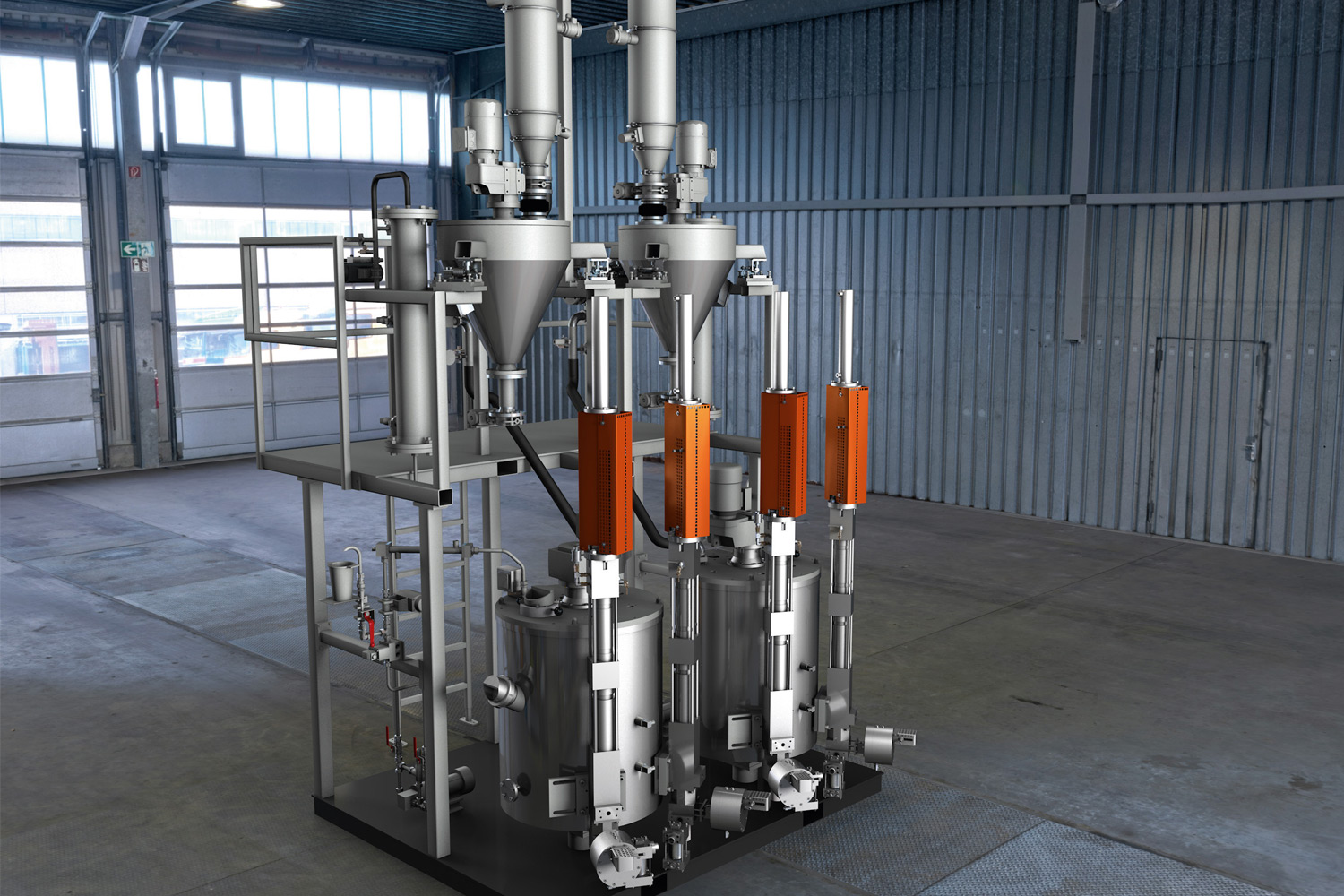

Resin Casting Equipment with MTB Technology for more Efficiency

The HEDRICH resin casting equipment with MTB technology (Multi-Top-Benefit) is suitable for the casting of all liquid and solid resin systems, highly abrasive fillers as well as plastic and glass microspheres, combining the individual process steps of pre-formulation, degassing and preparation to one group. Double to triple the formulation and preparation capacity ensures a nearly unlimited casting process. The result: Increased productivity by 200 percent!

|

|

More Productivity |

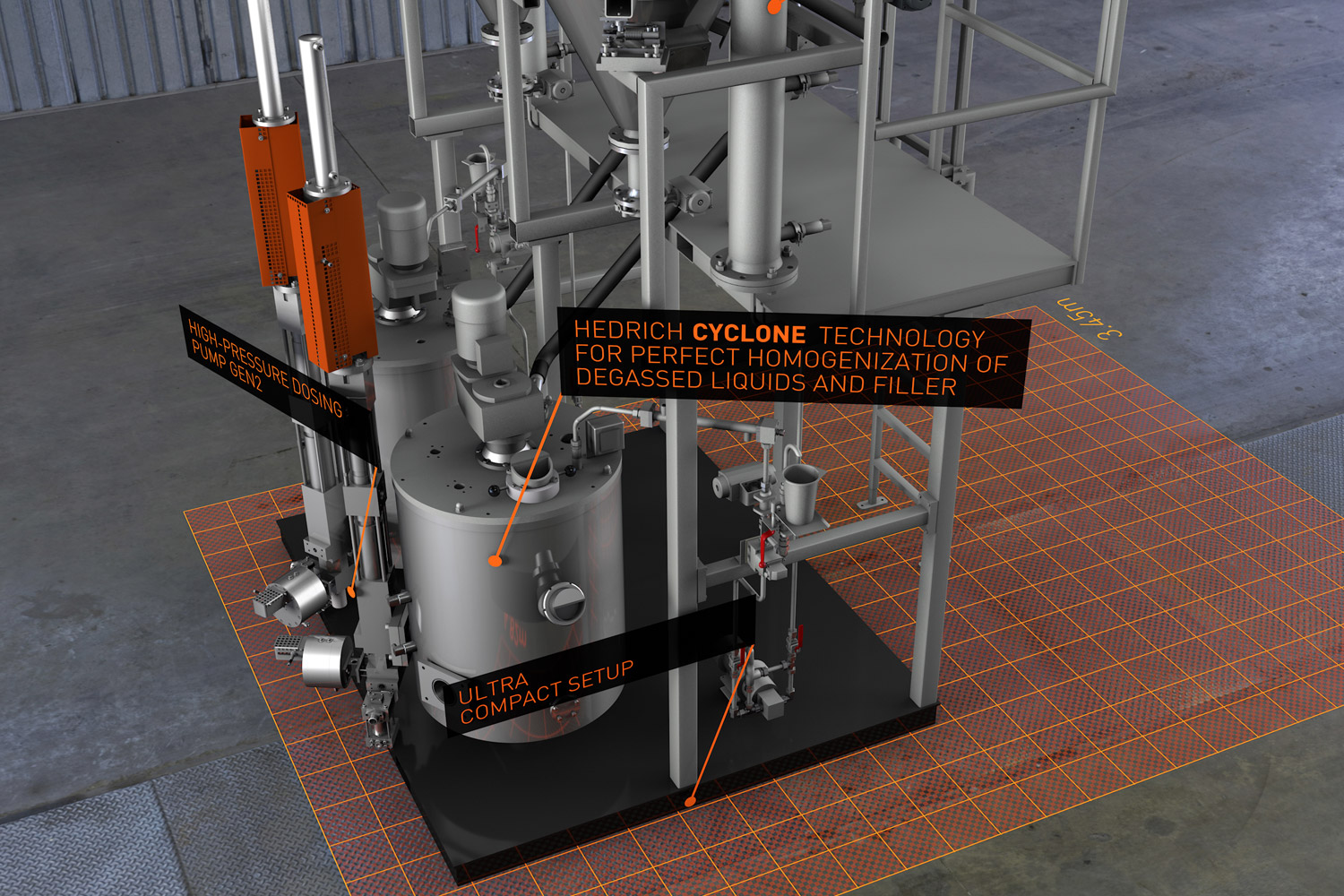

Equipment yet available on the market process abt. nine tons of casting material a day. The new MTB equipment is capable of handling at least 20 tons within the same period – depending on the specific production processes. This is achieved by preparing (degassing and drying) the casting components before formulation. In absolutely newly developed CYCLONE mixers, the prepared components are optimally homogenized in a continuous mixing process.

|

|

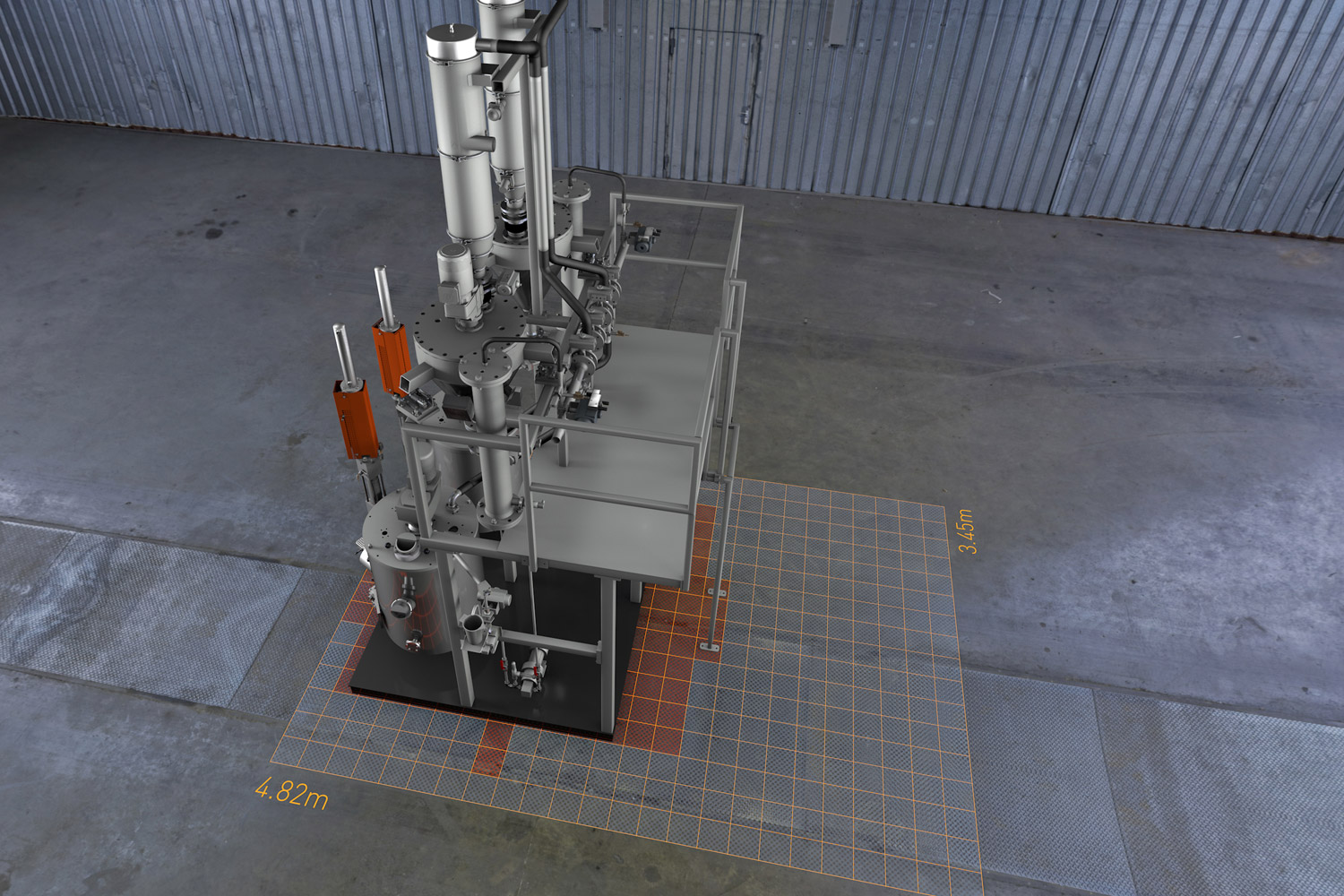

Ultra Compact Design |

Construction and function allows – depending on the required equipment properties – to save costs for the investment, start-up, operation and service significantly at a double digit rate. The acquisition price is about ten percent lower than for comparable equipment. It can be set up where it is actually needed, thus saving space, and is more compact. The operator saves a lot of time – both until the production starts and for maintenance, benefitting from the fact that the equipment has incorporated much less moving parts, which are thus subject to less wear. The sustainable design of our equipment grants a long-term operation – without long down times.

|

|

Lower Costs for Energy |

The Total Benefit of Usership (TBU) is deemed top-priority issue for the HEDRICH GROUP. This involves the overall cooperation of our experts with the customer: For the technical analysis, the ideal equipment design and realization and a customized maintenance schedule throughout the entire life time of the equipment. In addition, you will benefit from a reduction of energy costs by 13 percent for the respective material. This is how our resin casting equipment with MTB technology fits the bill.

Advantages of resin casting equipment with MTB technology

Advantages of resin casting equipment with MTB technology

• 30% lower costs for energy by efficient and precise preparation of the fed quantity as well as an „on-demand“ system

• 25% shorter start-up times by faster setting-up

• 20% less costs and time for maintenance and servicing and about 30% lower costs for spare parts due to less moving parts (involving wear)

• 10% lower investment costs than for comparable vacuum casting equipment