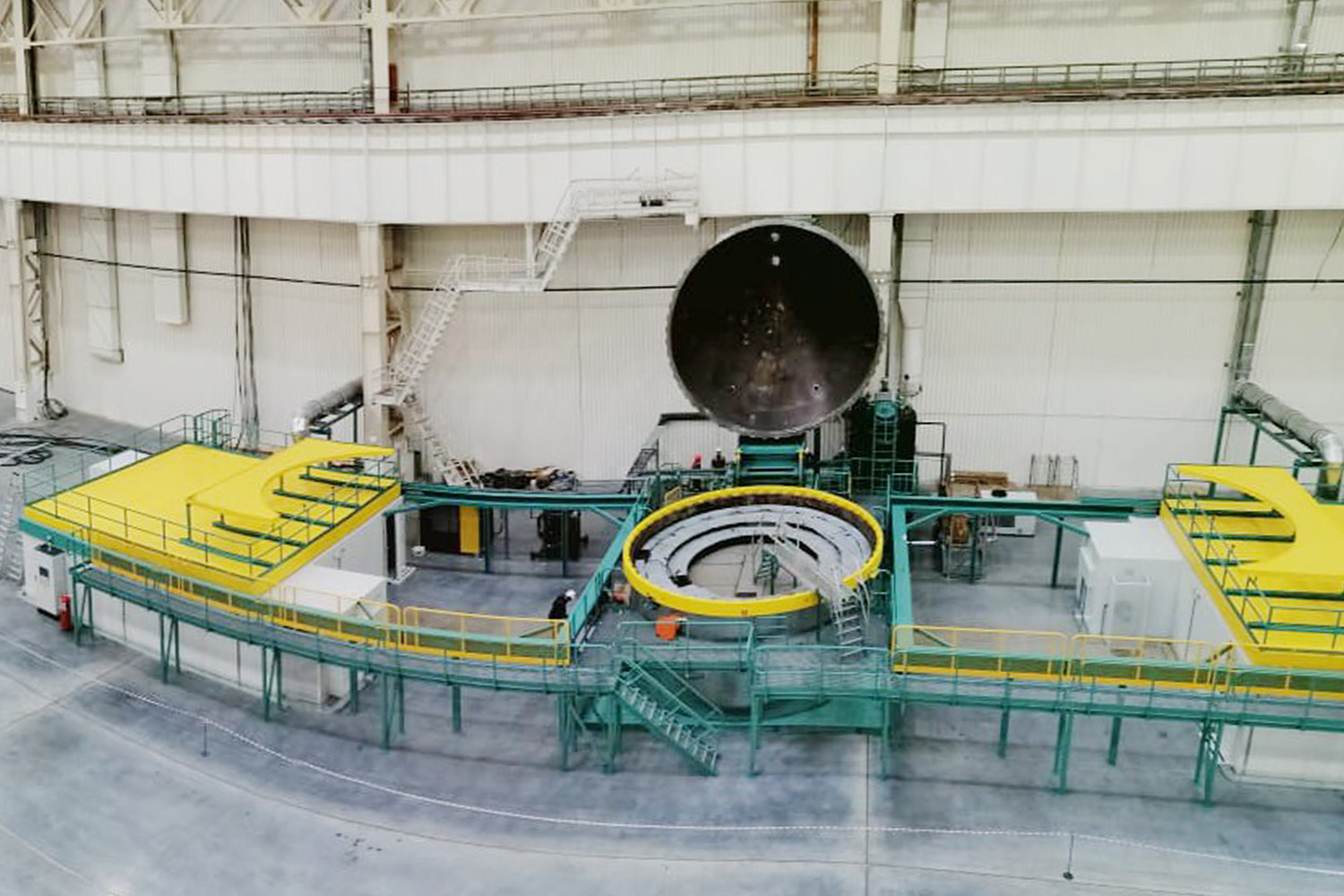

Optimum Equipment Solutions for Vacuum Pressure Impregnation (VPI)

HEDRICH designs and builds optimum equipment solutions for vacuum pressure impregnation – individually adapted to your requirements. For non-porous impregnation of most different components, insulating media such as varnishes, oils, resins and waxes are used. The parts to be impregnated are degassed and dried under vacuum and then impregnated by pressure application.

|

|

Complex Solutions |

Depending on your requirements, HEDRICH provides the impregnating systems with additional components, such as e.g. stirrer, cooling coil, exhaust devices or capacitance meters to control the impregnation.

|

|

Transport by Feeder Pump |

The impregnating medium can alternatively be transported by a feeder pump from and to the impregnating vessel. An option is to additionally heat up the impregnating medium in the supply pipe and to cool it down again in the return pipe thus allowing to adjust the viscosity.

|

|

Simple Conveyance by Pressure Difference |

Impregnating systems with transport by pressure difference are used when the impregnating medium does not need to be heated up. In most cases, the transport is performed under vacuum.

|

|

Compact Solution |

Compact systems can be used to impregnate small parts. In such cases the storage and impregnating tanks are arranged on top of each other. The impregnating medium is transported by pressure difference / gravity.

Advantages of vacuum pressure impregnation (VPI)

Advantages of vacuum pressure impregnation (VPI)

• Simple design using pressure difference

• For different impregnating media with varying viscosities

• Improved heat transport

• Noise reduction through avoidance of vibrations

• Equipment versions with heating/cooling, feeder pump and measuring technology

• Enhancement of electrical and mechanical properties

Applications

Applications

• Motors

• Generators

• Sintered metal parts

• Cast metal housings