To name just a few of our innovations let us introduce the on-demand principle for on-the-fly degassing in our batch equipment and our patented on-the-fly formulation units for a continuous preparation of the desired cast resin system.

Equipment for Cast Resin Insulation

Equipment for Cast Resin Insulation

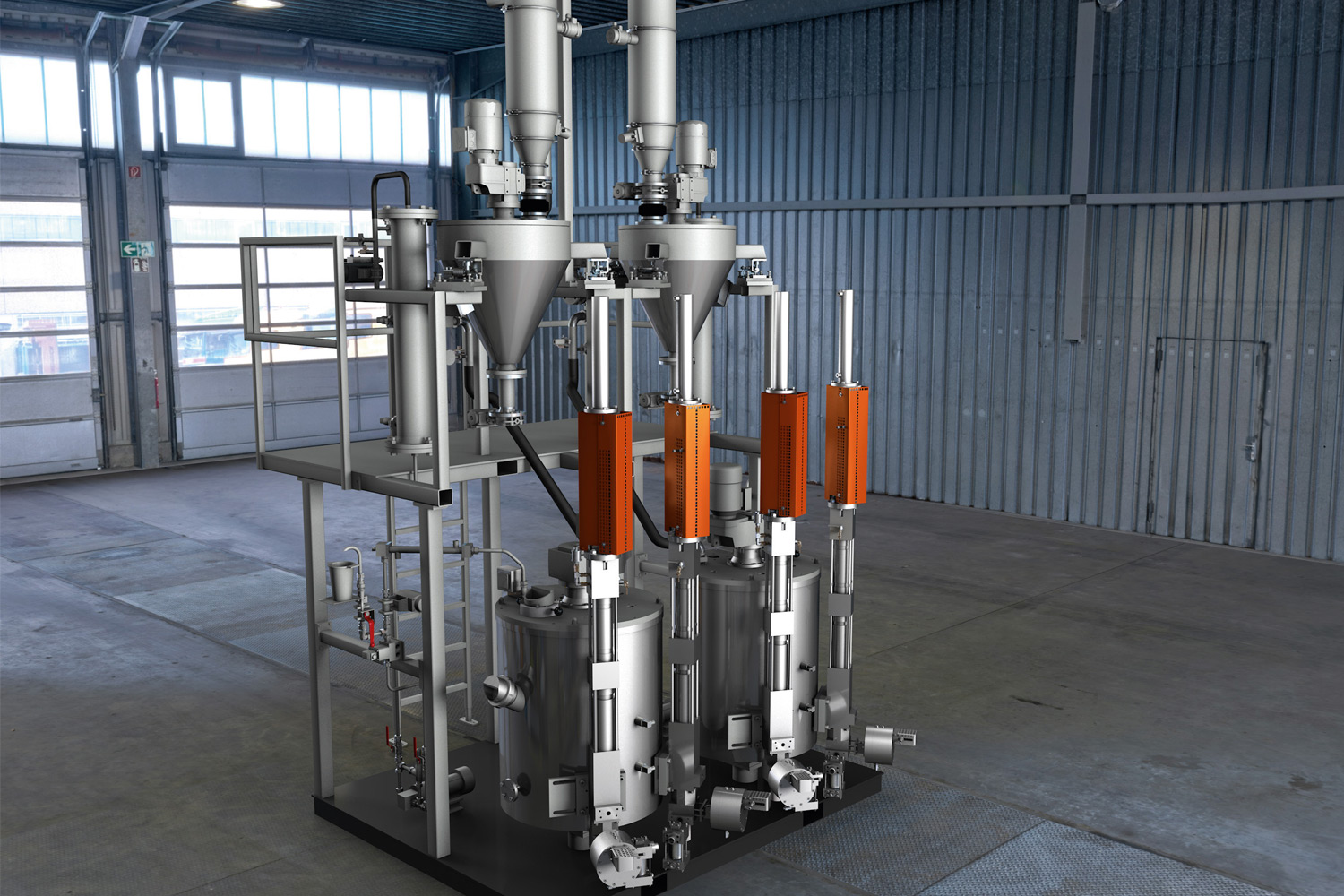

Wherever epoxy resin systems are processed for vacuum casting, this is where our design for preparation, mixing and dosing is implemented. Based on our decades of experience and in close cooperation with users, material suppliers and testing labs, we have permanently developed and perfected our vacuum systems for cast resin insulation.

To name just a few of our innovations let us introduce the on-demand principle for on-the-fly degassing in our batch equipment and our patented on-the-fly formulation units for a continuous preparation of the desired cast resin system.

To name just a few of our innovations let us introduce the on-demand principle for on-the-fly degassing in our batch equipment and our patented on-the-fly formulation units for a continuous preparation of the desired cast resin system.