Moulds for APG and LSR – for High-Quality Components

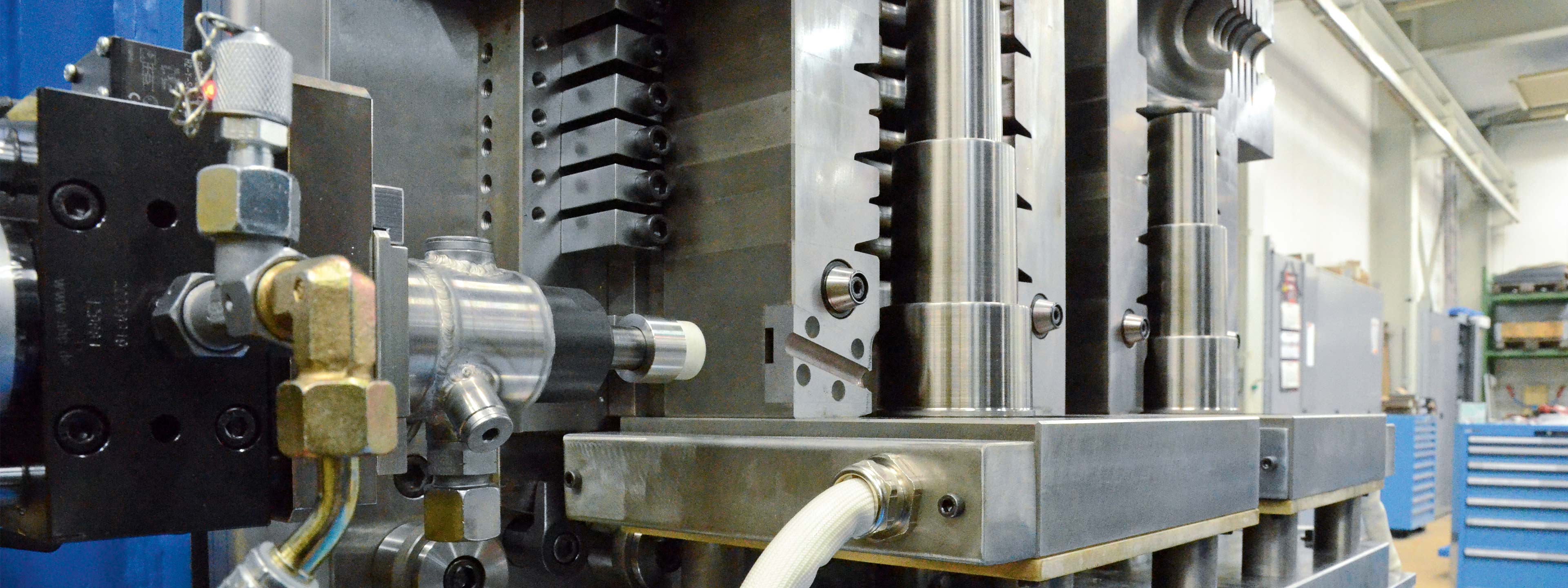

VOGEL moulds – either for APG process or silicone applications (LSR) – are dedicated to highest precision and reliability. Every single mould has exactly been adapted to the machine, granting high-quality components from the beginning. The moulds are designed and developed by means of technically most advanced 3D CAD systems. They meet the requirements on production, which are growing more and more complex and fast.

|

|

Long Service Life and Precision |

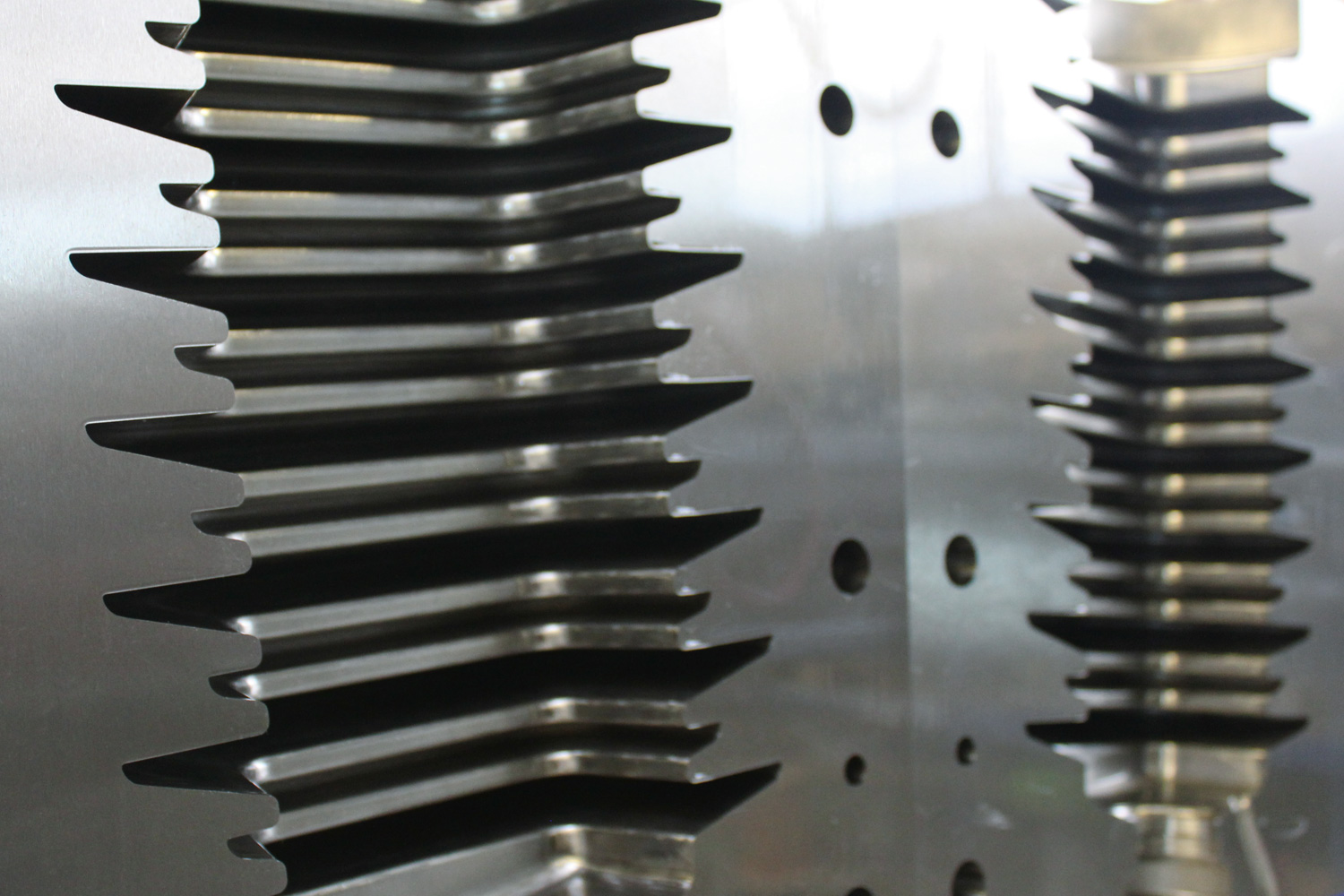

With the modern mould arrangement it is possible to manufacture faultless dimensionally stable parts from the first shot. Each mould exactly fits the customer’s requests and provides a convenient, easy handling in perfect correlation with the clamping unit. Thanks to high-quality materials and high-tech thermal treatment, the moulds’ service life is very long.

|

|

Modular and Extendable |

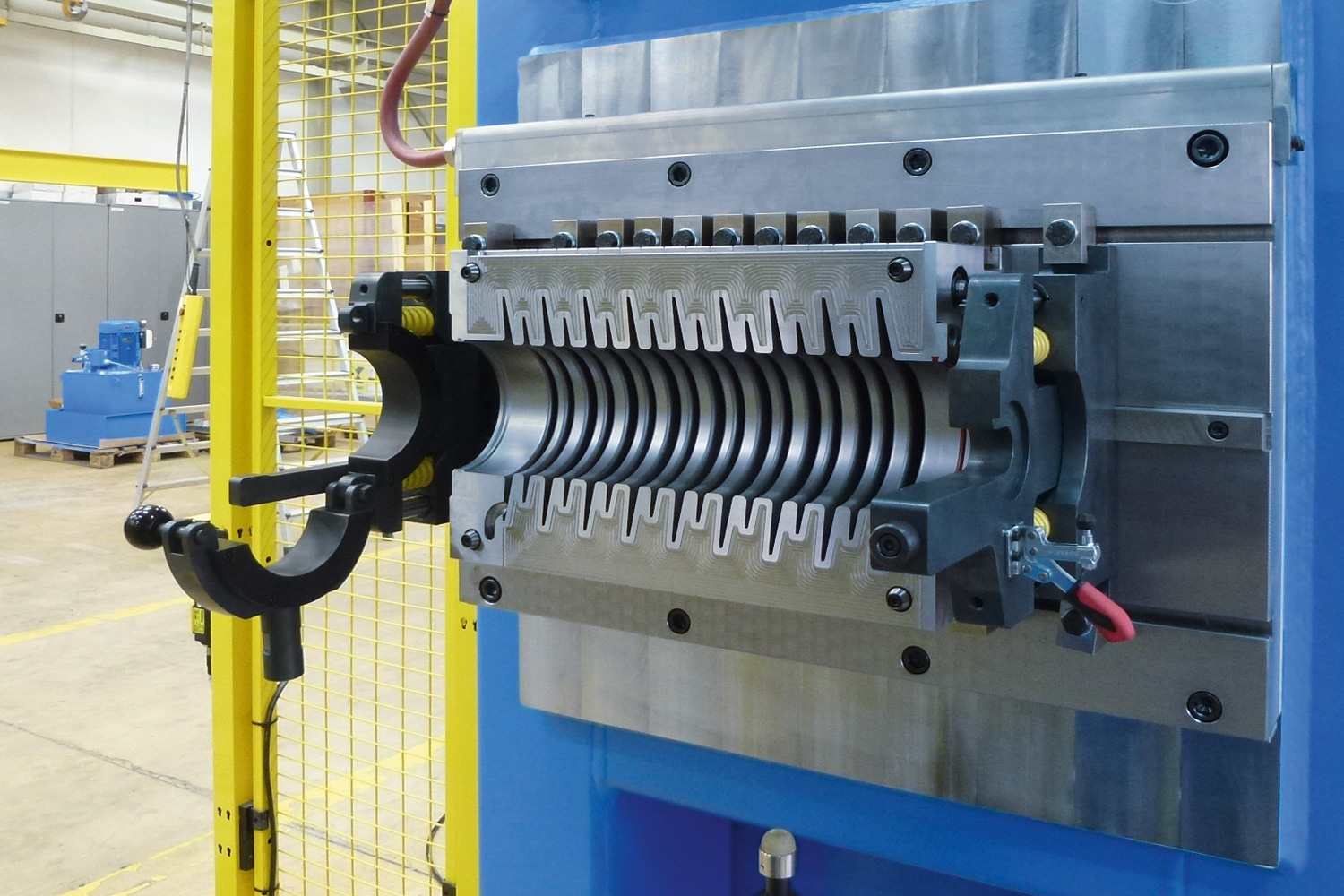

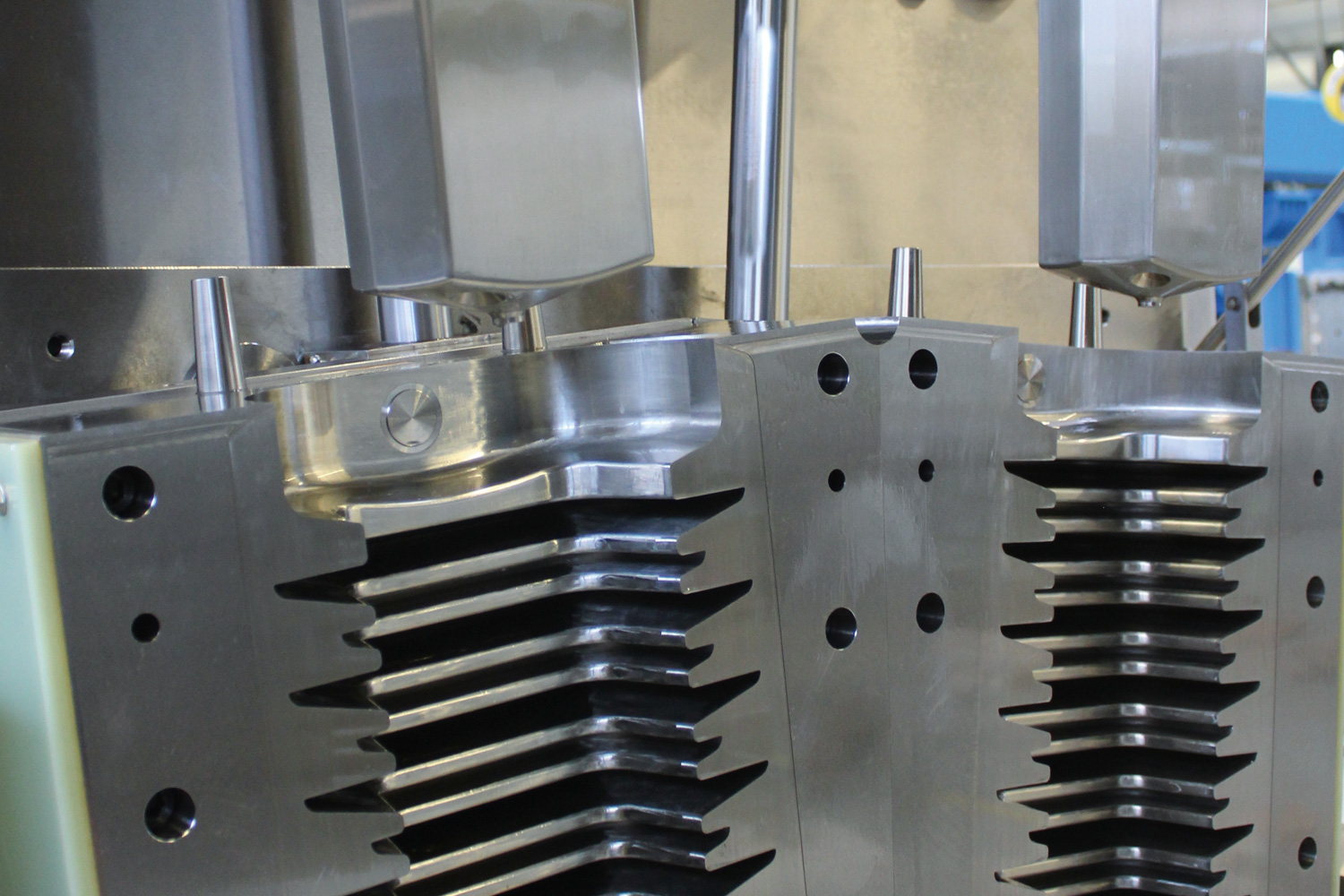

If requested, different – even complex – components can be manufactured with just one mould. The flexible APG moulds employ exchange kits or variable mould bricks. Every mould can have one or several independently moving core pullers. The modern block arrangement of the LSR moulds allows a short, easy change-over of insulators of various lengths.

|

|

Directly or Indirectly |

All moulds – both for APG and LSR – can be equipped with direct heating or be heated indirectly via the heating plates of the machine. The moulds for LSR can either be brought to the required temperature electrically via heating cartridges or by means of heat/cool channels via external heating/cooling units.

|

|

Technically Matured |

The applied materials and high surface quality result in a considerable reduction of the maintenance and cleaning efforts when changing the mould. In order to increase productivity, a mould may have up to eight cavities. As a matter of course we consider sophisticated pour-in systems as well as fully automatic demoulding and moulding systems.

Advantages of moulds for APG and LSR

Advantages of moulds for APG and LSR

• Manufactured for highest precision and extremely long service lives

• Maintenance and user-friendly setup

• Easy assembly and handling

• On request, modular arrangement to allow different parts to be manufactured with one mould

• Electric heating, heating/cooling and cooling integrated into the mould

• Intelligent pour-in and vent systems

Applications

Applications

• Switch housings with and without integrated vacuum tube

• Insulating parts for medium and high voltage switch gears

• Hollow insulators up to 1,100 kV, long-rod insulators up to 400 kV

• Arresters

• Manufacturing as well as encapsulation of cable sleeves up to 500 kV