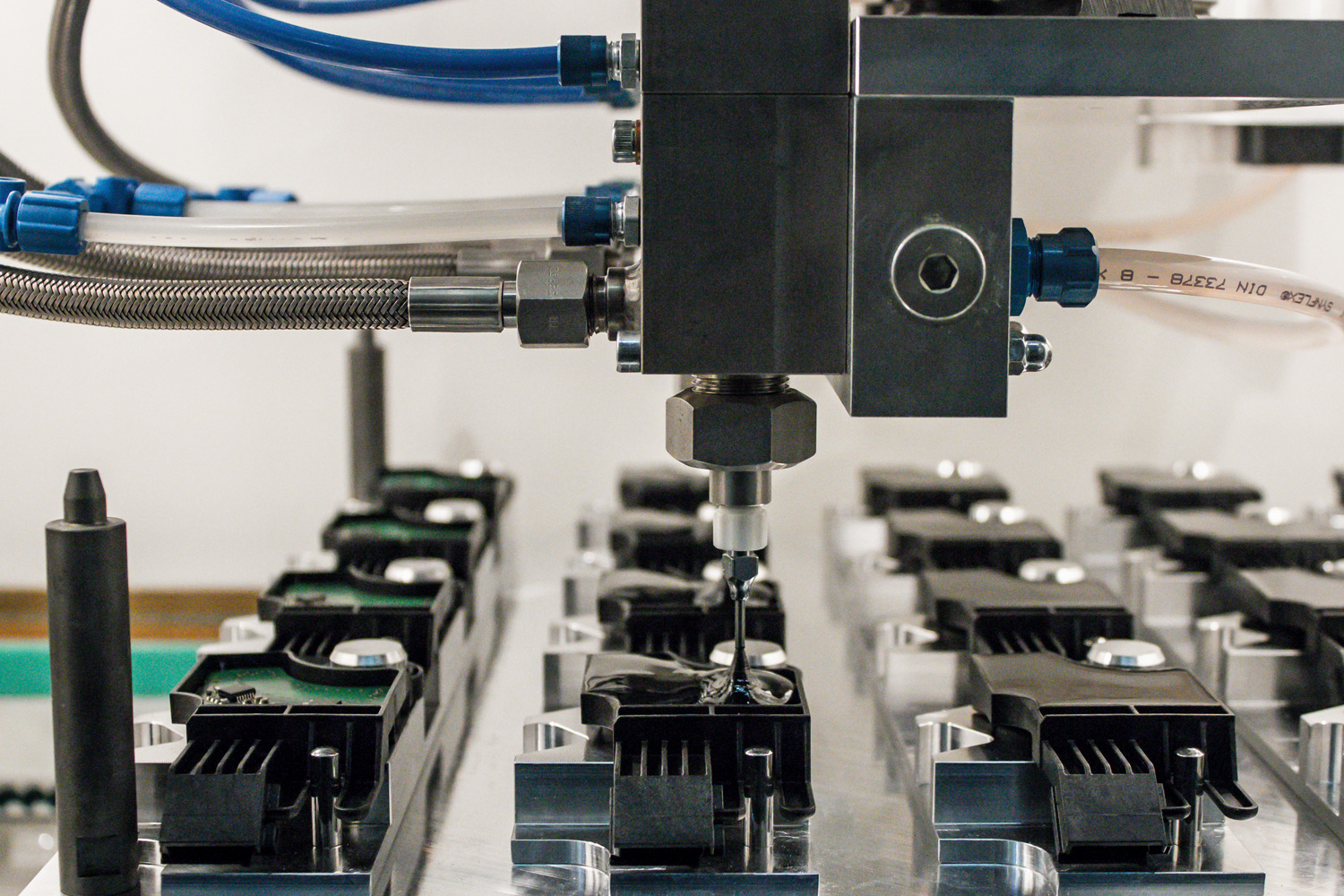

Vacuum Shot Dosing Equipment for Optimum Potting Casting of Electronic Components

Automotive ignition coils, sensors or small transformers – HEDRICH develops vacuum shot dosing systems for the highly precise potting of electronic components under vacuum. The partially or fully automatic special potting casting equipment can either be integrated into an existing production line as stand-alone unit or supplied as complete line including continuous tunnel drying ovens, plasma systems and continuous curing ovens.

|

|

Maximum Flexibility |

The HEDRICH 3D casting system provides highest flexibility in production irrespective of height, width or geometrically variable part sizes. The casting nozzles are moved to the component and not vice versa. The up-to-the-rim filled parts are moved as little as possible to avoid spilling of the casting compound. Simultaneous movement of casting nozzles and pallets optimizes the potting process, thus minimizing the cycle times.

|

|

Faultless Dosing |

Most dosing supervision systems only detect a fault in the filling quantity during casting, thus generating unnecessary waste by casting errors. And then there is our new HEDRICH PreCHECKTM system! It recognizes an improper dosing of the cast resin components yet before potting, and therefore avoids waste.

|

|

Extremely Sturdy |

The casting nozzles of all HEDRICH shot dosing systems are provided with ceramic-made closing pins as standard. These extremely wear-resistant closing pistons grant very long service life with a highly precise and drip free casting.

|

|

Detailed Protocol |

To increase the process quality assurance, all component-specific casting parameters are stored in a database system, enabling a detailed retraceability of each cast component.

Advantages of vacuum shot dosing equipment

Advantages of vacuum shot dosing equipment

• Highest flexibility by 3D casting system

• Full-ceramic dosing pistons with extremely long service intervals

• 3-chamber vacuum casting tank for max. productivity

• Inside or downstream TopOff casting with automatic measurement of the cast resin compound level

• Casting of cast resin with abrasive fillers

Applications

Applications

• Small transformers

• Sensors

• Electric motors

• Electronic small parts