Isostatic Presses

Short circuit currents may cause forces in the windings leading to deformation. To ensure that these forces can be absorbed by the windings, these need to be preloaded. The isostatic presses of HEDRICH reduce the plastic deformation component by pressing the winding during the drying process in the oven. They are optimally designed for being used in hot-air and in vapour phase ovens.

|

|

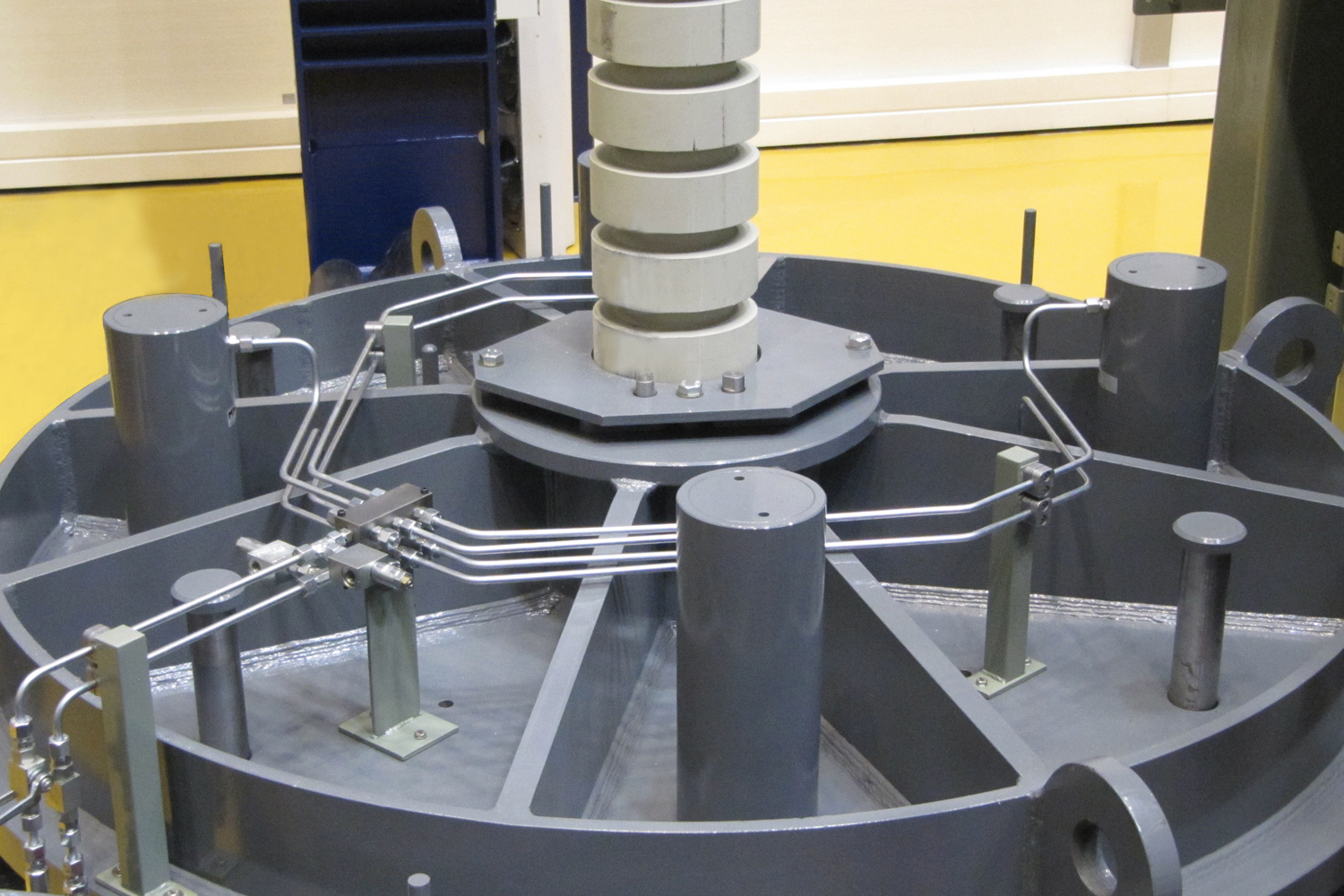

Isostatic Press with Central Cylinder |

The core of this pressing process is a pulling central cylinder. This cylinder uniformly pulls the mobile upper pressing plate against the winding as well as the lower pressing plate thus stabilizing the winding. The operating pressure of the hydraulic unit is 250 bar. Pressing forces up to 3,200 kN are possible.

|

|

Several Cylinders for Small Winding Diameters |

For windings with a small inside diameter a pressing tool with several small cylinders at the upper pressing plate is recommended. Smaller cylinder cross sections require larger hydraulic pressures to achieve a pressing force of up to 3,200 kN. In this case the hydraulic pressure is 500 bar.

|

|

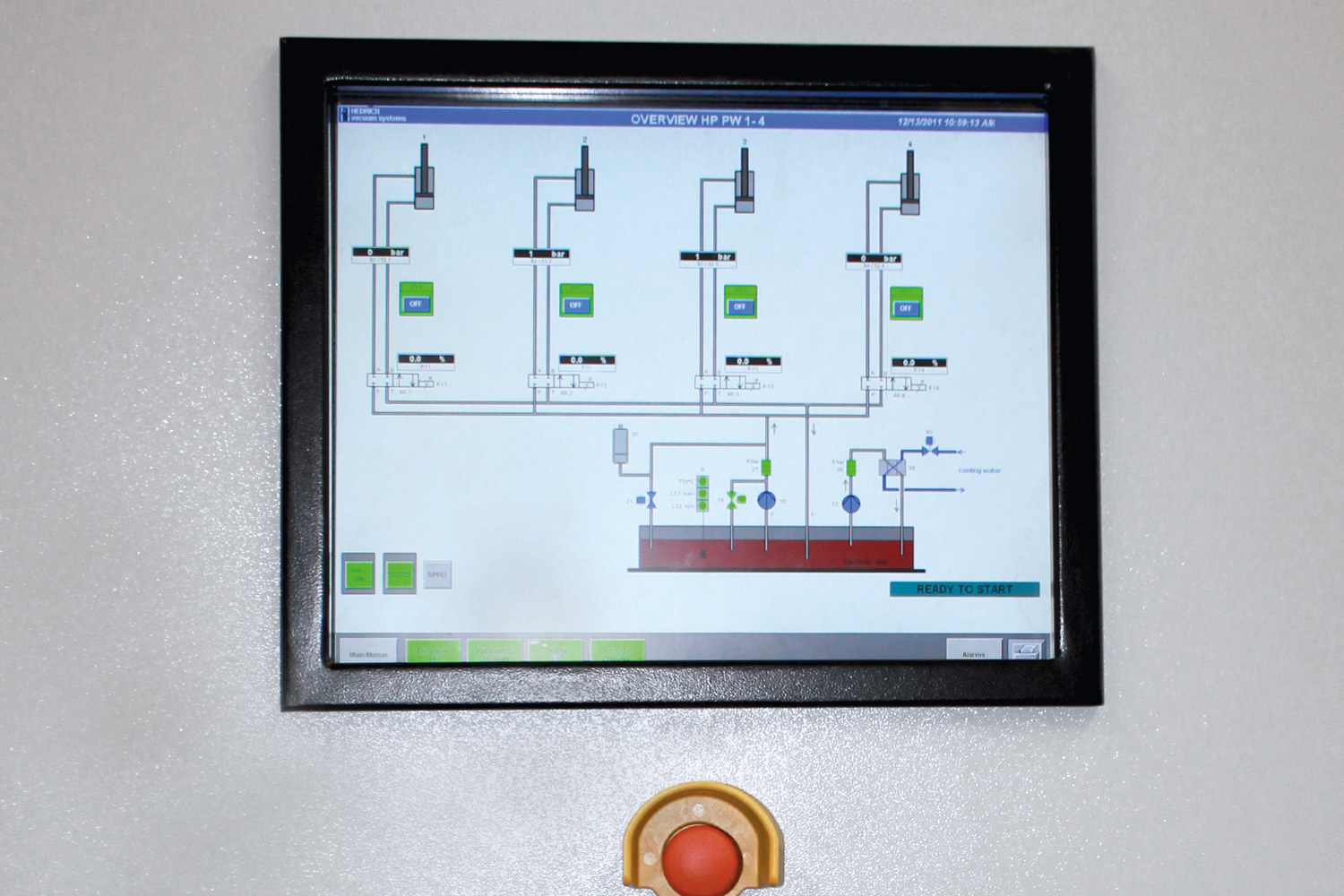

Automatic Control of the Pressing Process |

A computer system controls the pressing process. The entered parameters are the ultimate force to be achieved as well as the pressing and holding times for reaching individual pressure increase curves. The pressing process takes place fully automatically. It is represented visually and can also be printed out.

|

|

Length Measurement |

To check the length variation of the windings during the pressing process, length measurement systems can be fixed to the pressing tools. Inductive way measurement has proved to be optimal. The control of the length variation serves among others as quality proof.

Advantages of isostatic presses:

Advantages of isostatic presses:

• Pressing tools adapted to the winding sizes

• Isostatic presses of active parts

• Mobile hydraulic unit to load and unload the pressing tools

• Length measurement systems available as option

Applications

Applications

• Single windings

• Winding blocks

• Active parts