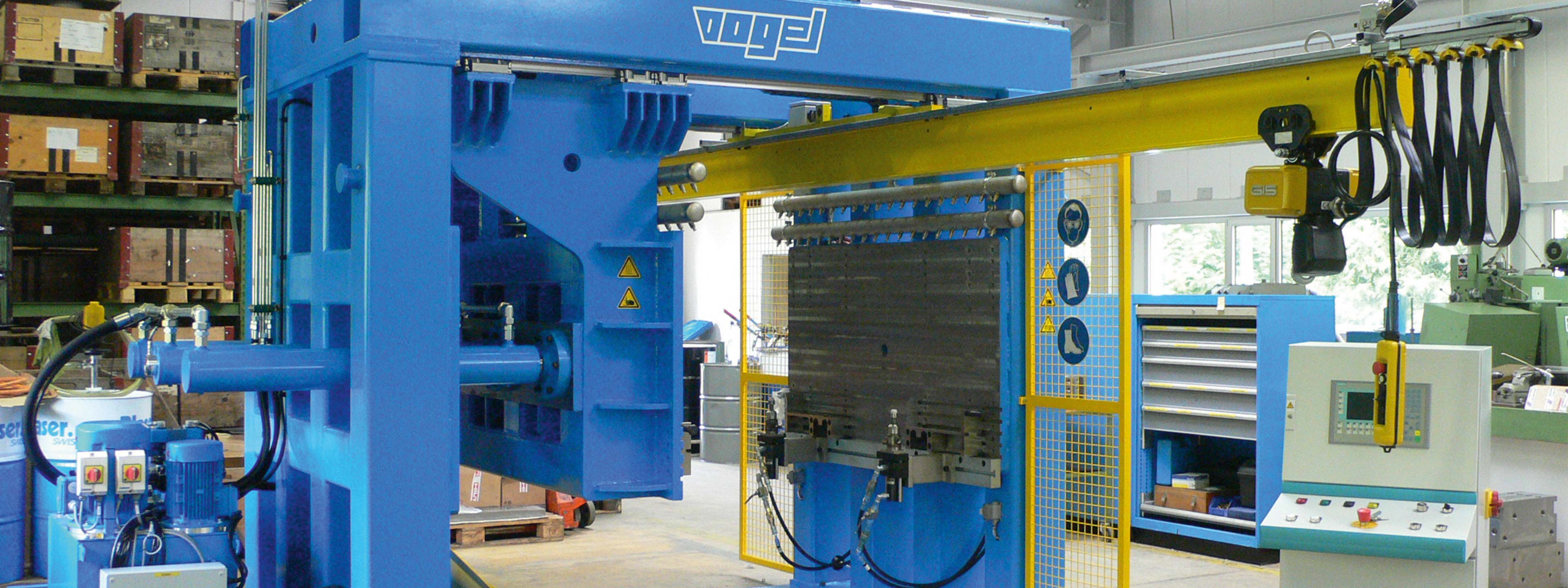

Sturdy LSR Clamping Units for the Manufacturing of Insulators

VOGEL clamping units for the casting of liquid silicone rubber (LSR) are based on the proven principle of the APG clamping units. Therefore, they are in the same way reliable, sturdy and built for maximum clamping force. Each machine is designed so that it can take up even huge moulds up to several tons without any problem.

The intelligent principle and free accessibility from both sides allow to manufacture insulators with lengths that exceed the machine width by a multitude. The machines can be loaded by means of simple, manual crane systems or most advanced fully automatic handling systems to put in the several meters-long insulators and rods and mount even moulds weighing tons easily and safe.

|

|

Powerful and Sensitive |

All machines have a generously dimensioned rigid machine frame, which is optimized for taking-up tools up to 8 tons per mould half. The massive moving carriage suspends from reinforced precision guidances and can be adjusted according to the weight. This allows parallel closing as well as clean and smooth opening of the clamped moulds.

|

|

Comfortable and Safe |

Employing modern safety switch devices allows to operate the machine without any disturbing protective fences. This ensures easy and uncomplicated charging of the moulds with the composite tubes and rods, which can be up to 20 m long.

|

|

Quality by Pressing a Button |

Just one click on a button is necessary for the modern, intuitive control to change a screen and edit parameters quickly. All functions like cylinder positions, heating parameters (temperatures and PID values) and hydraulic pressures are clearly split up. The process-relevant steps can be selected from a library and stored as program along with the other parameters.

|

|

Less Wear – Less Costs |

Thanks to the simple, modern mechanical arrangement, maintenance and service is minimized. No components are used that are subject to excessive wear. Therefore, the maintenance and down times per year as well as costs arising for maintenance and service are very low.

Advantages of LSR clamping units

Advantages of LSR clamping units

• Best accessibility from both sides

• Modular extendability (fully automatic handling units, mould crane and crane for parts handling)

• Clear intuitive control, freely programmable

• Pour-in systems for individual and multiple casting

• Special equipment such as hydraulic quick-clamp systems and vacuum chambers for the arrester production

• Heating of the moulds – electrically and by means of heating/cooling units

• All components made by renowned manufacturers – worldwide availability of spare parts

Applications

Applications

• Long-rod insulators up to 400 kV

• Arresters

• Encapsulation of cable sleeves up to 500 kV

• Direct shielding of bushings

• Manufacturing of cable sleeves and accessories