Special Equipment and Solutions for Automation, for an Efficient Manufacturing Process

VOGEL supplies different kinds of special equipment and solutions for automation for an efficient and top-quality manufacturing process. Our experience in machine, mould and equipment engineering as well as in the process technique for manufacturing components according to the APG process or silicone process is the basis for innovative and practicable solutions. Our philosophy is „from specialists – from one source – from the start”. Yet when designing the product, VOGEL is available to you with great experience in order to gain best conditions for an efficient production launch-out with high quality manufacturing later.

|

|

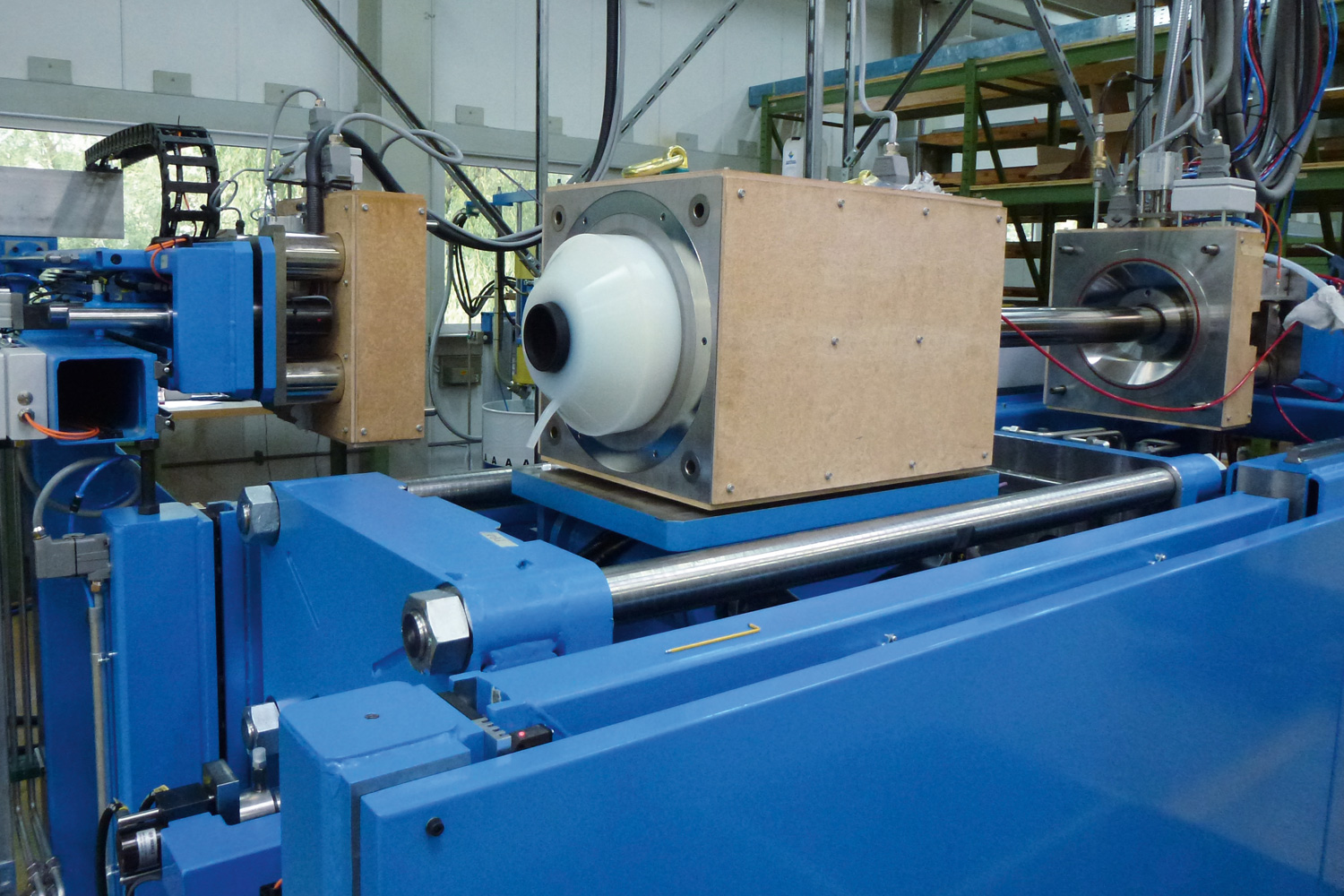

Time-Optimized Manufacturing |

For the manufacturing of cable sleeves up to 500 kV, VOGEL provides a fully automatic production equipment. The applied moulds hold integrated pressure and temperature sensors to monitor an optimum filling and vulcanization process and are swiveled as necessary for optimum filling. This equipment reduces the manufacturing time by 50% compared with other commonly available processes.

|

|

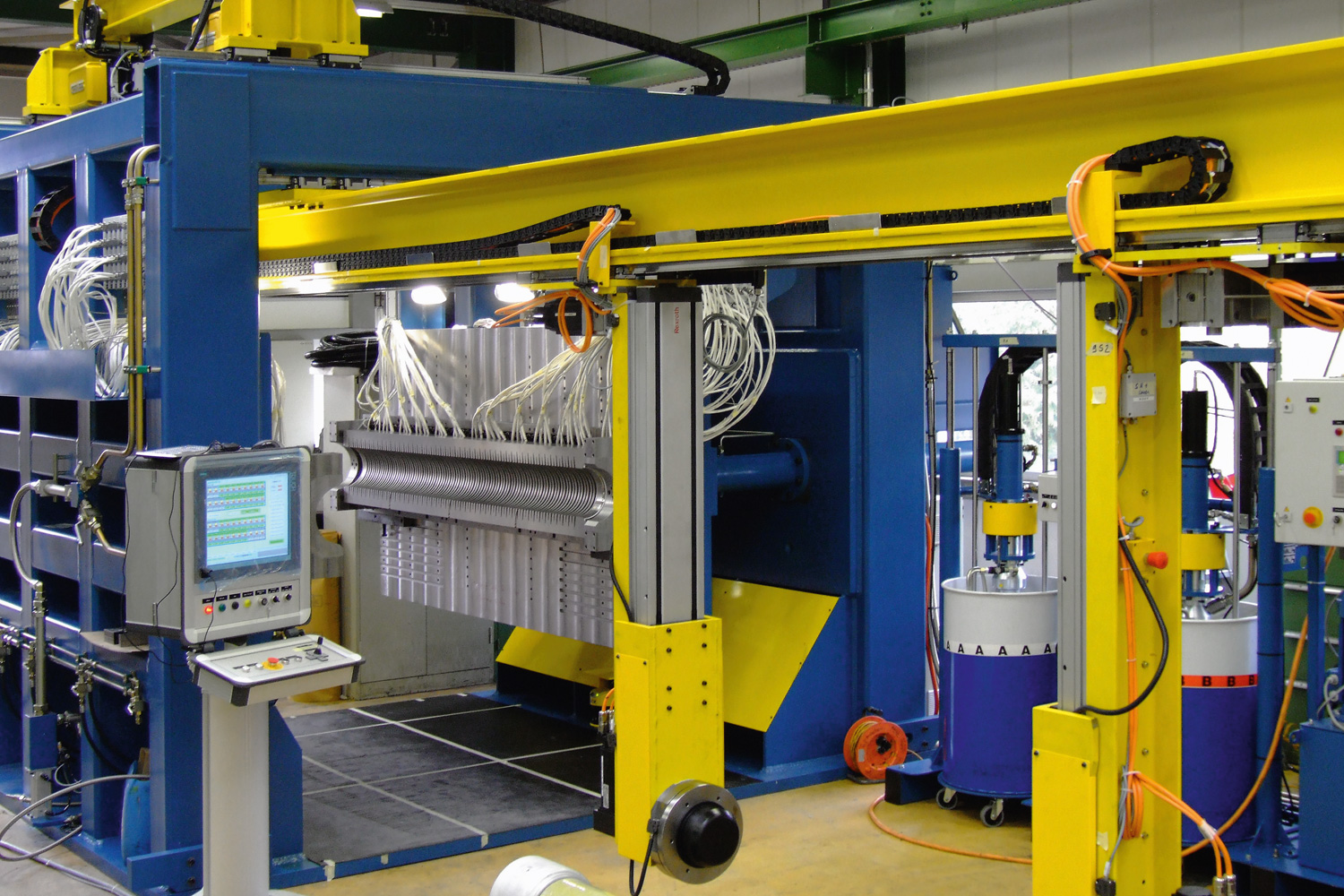

Fully Automatic Manufacturing |

For manufacturing electric drives, VOGEL has developed a fully automatic system that loads and unloads as well as preheats components, casts and finally post-cures them. The modular arrangement allows an extension in steps as well as mixed production of several types.

|

|

Constant Mixing and Dosing |

VOGEL always grants a homogeneous mixing ratio for highly viscous filled materials (e.g. 2K adhesive materials) as well as at very different viscosities of the components. Permanent circulation under vacuum excludes sedimentation, and a steadily proper mixing quality of the components is ensured.

|

|

Automation of Processes on Standard Clamping Units |

To optimize processes, VOGEL provides a great number of automation solutions for the standard clamping units – such as handling systems for loading and positioning the GFK pipes when manufacturing composite insulators in multishot process, loading slides for loading and unloading and automations with robots for mould cleaning and parts handling.

Advantages of special equipment and solutions for automation from VOGEL

Advantages of special equipment and solutions for automation from VOGEL

• Corresponding to the machine directive 2006/42/E

• Own long-term experience in machine, mould and equipment engineering

• Experience in process technique for APG and silicone processes

• From development, manufacturing, start-up to service – all from one source

Applications

Applications

• Manufacturing of high voltage cable accessories up to 500kV

• Robot-based automation solutions

• Parts handling for shielding of hollow insulators

• Dosing and mixing of highly viscous and abrasive materials

(adhesive material, epoxy, etc.)