Vacuum Drying and Impregnating Equipment for Electric Components

Modern and effective drying and impregnating systems providing the best dielectric and mechanical properties to the oil/paper-insulated electric products are preferably operated using vacuum. This applies to the purification of the insulating oil as well as to the drying of the insulation. We supply vacuum drying and impregnating systems and oil purification units that are individually adapted to the requirements of oil/paper-insulated electric products like HV instrument transformers, capacitors, bushings and other electric components voltage range.

|

|

Ten Times The Productivity |

The continuous systems of HEDRICH allow to achieve high throughputs of more than 1,000 capacitors per week (90 to 120 capacitors per week in batch systems). A downstream automatic oil filling and pressure test is also possible with continuous systems.

|

|

Individual Filling Heights |

We offer a multitude of different filling systems. The filling heights can be adjusted via a common open channel in the vacuum tank itself or on the outside according to the principle of communicating pipes. Individual filling vessels offer highest flexibility.

|

|

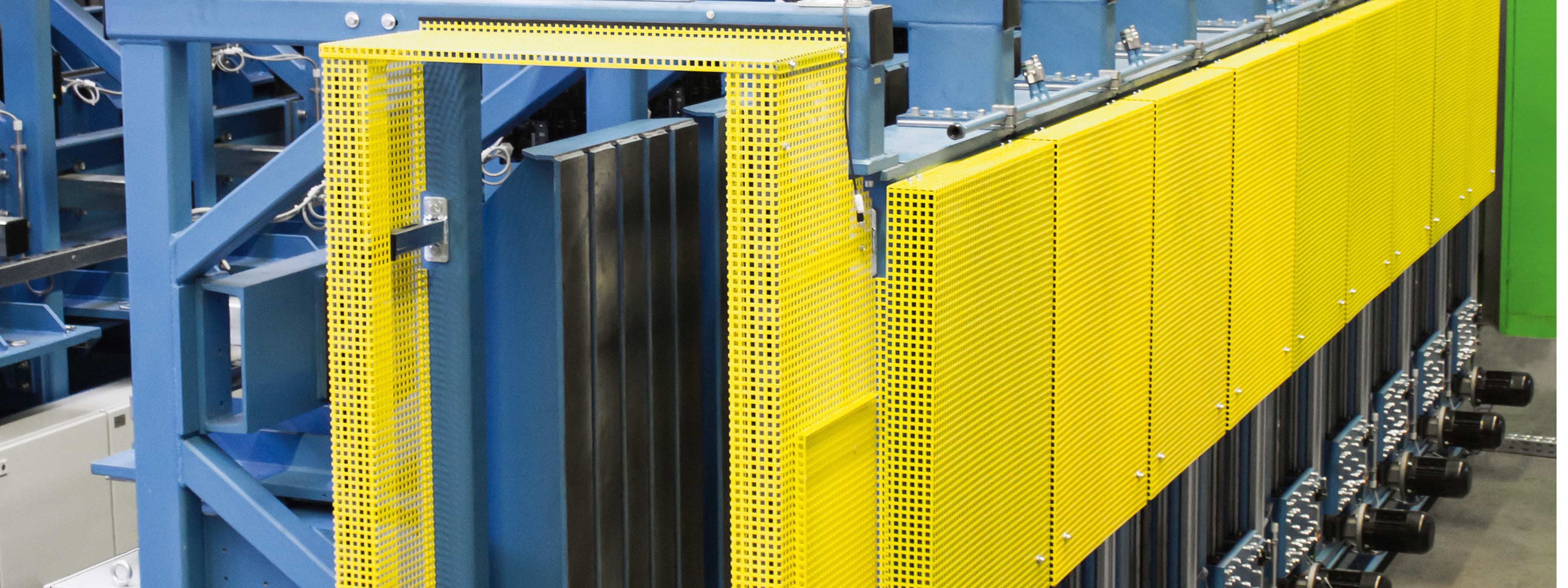

Optimum Room Utilization |

With compact construction and shortest ways, the HEDRICH equipment concepts are the basic elements for maximum productivity. The loading systems are adapted to the respective products so that the resource productivity of the industrial useful area can be increased by an optimum arrangement of the products.

|

|

Uniform Temperature Control |

HEDRICH heats and cools the complete autoclave on all surfaces, including top, bottom, rear wall and door. The temperature is controlled via different heating circuits with manual control valves. The typical heating medium is heat transferring oil that is pumped through welded-on U-shaped tubes. For acceleration, heating/cooling registers can be integrated between the parts to be dried in the autoclave.

Advantages of vacuum drying and impregnating systems

Advantages of vacuum drying and impregnating systems

• Different possibilities of filling and filling height adjustment

• Complete heating of autoclave by heat transferring oil, including door

• Optimized arrangement of heating/cooling registers for short heating and cooling times

• Optimized arrangement of the capacitors on special loading systems

• Optimized heat distribution through fans and air baffles (continuous)

• Option to dry under nitrogen

• Special filling ports for complete filling of the capacitor

• Loading of autoclave in space saving 2-level version

Applications

Applications

• Voltage/current instrument transformers

• Capacitive voltage instrument transformers

• Bushings

• Oil/paper-insulated electric componlents