Compact Potting Equipment

Thanks to HEDRICH‘s high process expertise combined with the use of the latest technologies, the system delivers perfectly prepared and degassed material for all potting applications.

The smartLine ensures high process reliability and offers high performance even for complex components and the highest quality requirements. The system concept can be configured for any type of application.

|

|

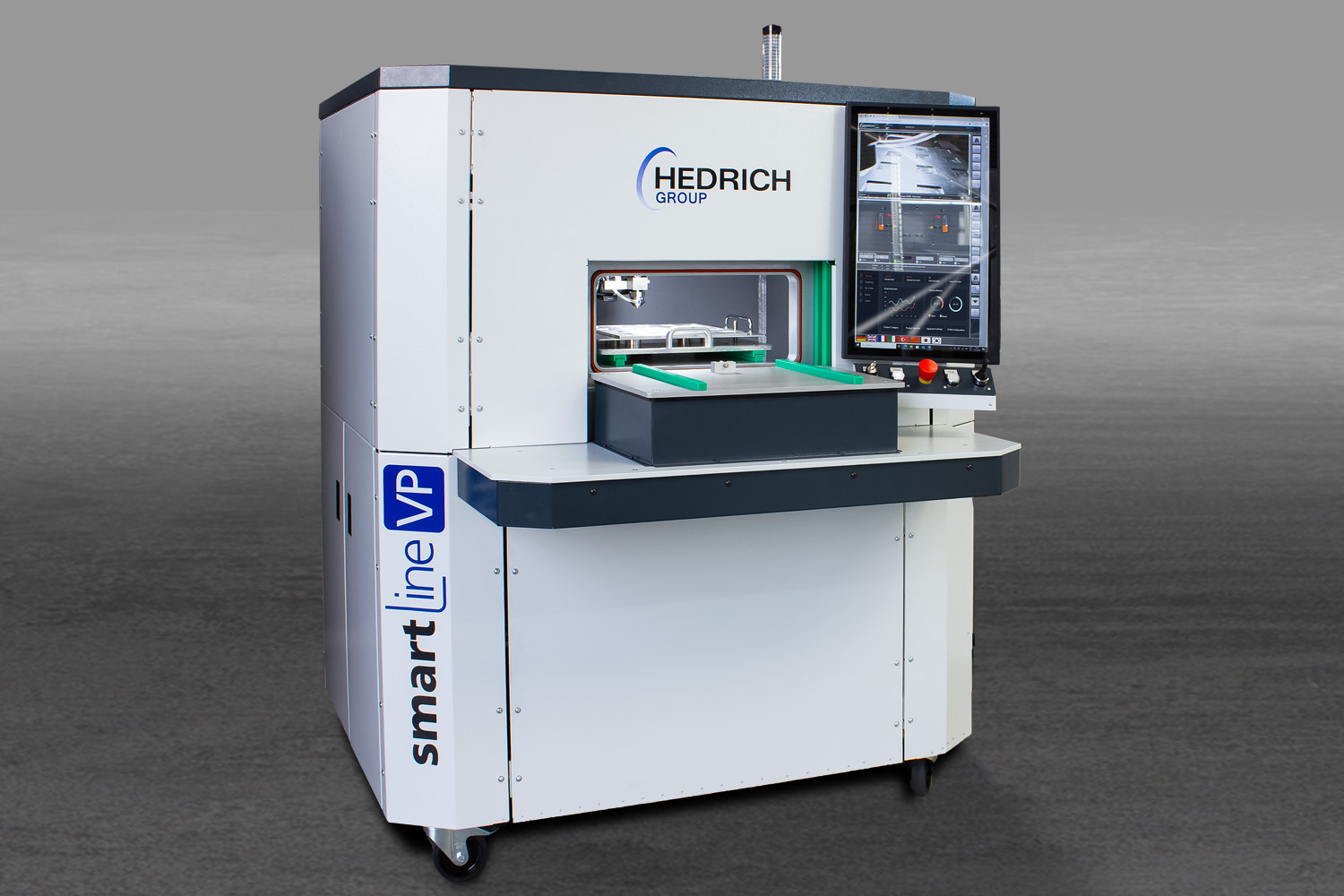

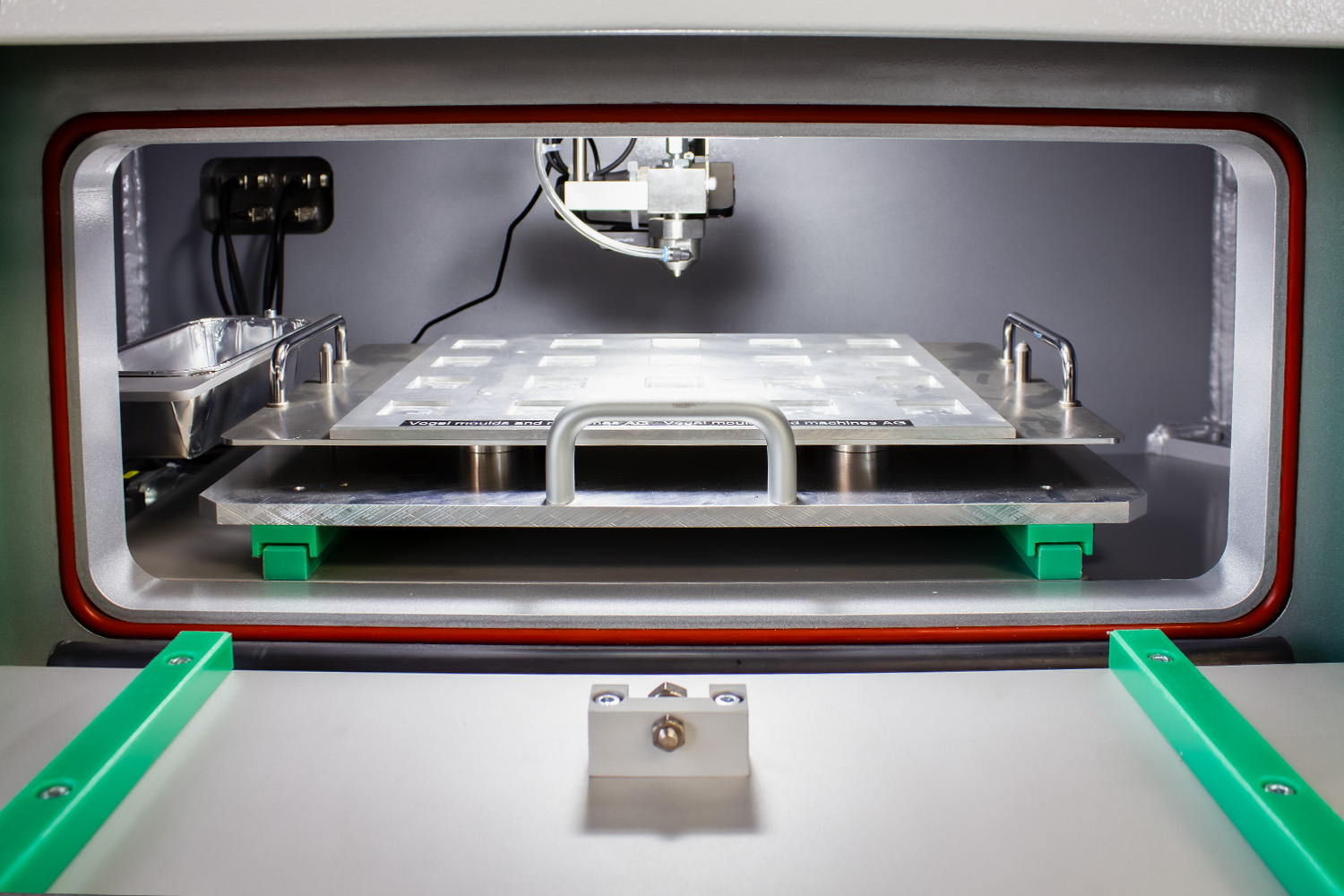

smartLine VP |

The smartLine VP can be equipped with an integrated camera that provides an optimal view of the components during potting. The vacuum chamber is available with either front or side loading (tunnel system).

A multi-chamber system with an entry and exit chamber is also available.

|

|

smartLine preparation unit |

The compact and mobile design, as well as the freely combinable mixer sizes for components A and B (30/45/60 liters), make the smartLine preparation unit universally applicable in the manufacturing process.

Whether for series production or test pottings in various applications, the smartLineTM is equipped for all tasks thanks to the latest HEDRICH dosing and preparation technology. Even highly filled resin systems with abrasive fillers pose no problem for the smartLine.

|

|

EFFICIENT. MODULAR. MOBILE. : SMART |

Whether potting under vacuum or atmospheric pressure or for manufacturing according to the Automatic Pressure Gelation process (APG), the size of the mixing vessels, the type of dosing/conveying, and the heating can be modularly assembled for the specific application.

The smartLineTM is easy and intuitive to operate and features an exceptionally maintenance-friendly design.

Benfits of the smartLine compact system

Benfits of the smartLine compact system

• Simultaneous preparation/dosing of 2 components

• Heating up to 90 degree C

• Vacuum down to 1 mbar

• Thin-film vacuum degassing

• For filled and unfilled resin systems

• Suitable for dosing devices or for direct dosing