Vacuum Infusion Equipment for the Production of Rotor Blades and Composite Components

HEDRICH vacuum infusion equipment (VIA line) have already established themselves successfully for the production of rotor blades for wind energy systems, offering significant advantages too for the production of high-quality composite components compared with other manufacturing processes. The consequent process under vacuum considerably increases the product quality, so cost-intensive reworking becomes completely obsolete. Constant quality on highest level along with the minimization of production and disposal costs for mate-rial loss – the fully automatic HEDRICH vacuum infusion concept is the most efficient solution for the high demands on the composite market.

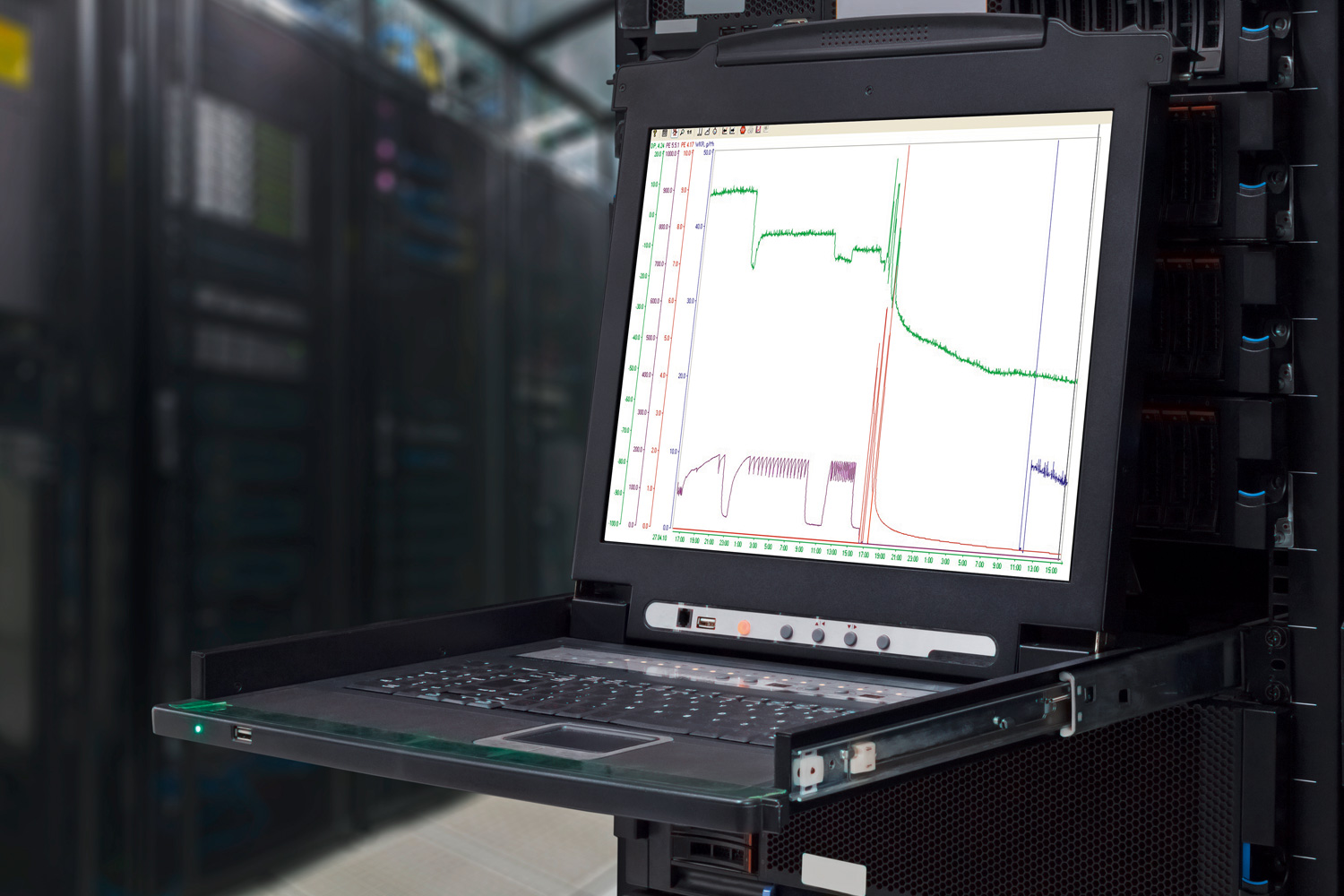

Residual Moisture and Gas Content Measurement

The HEDRICH VIA line provides a system to measure the residual moisture of fibre and core components. The fully automatic residual moisture and gas content measurement for unfilled cast resins by HEDRICH is the world’s first in the field of cast resin. The technology to measure the residual moisture having proven its excellence already in the range of the transformer oils has now been developed as exact measuring method for unfilled cast resins as well.

|

|

No Refinishing |

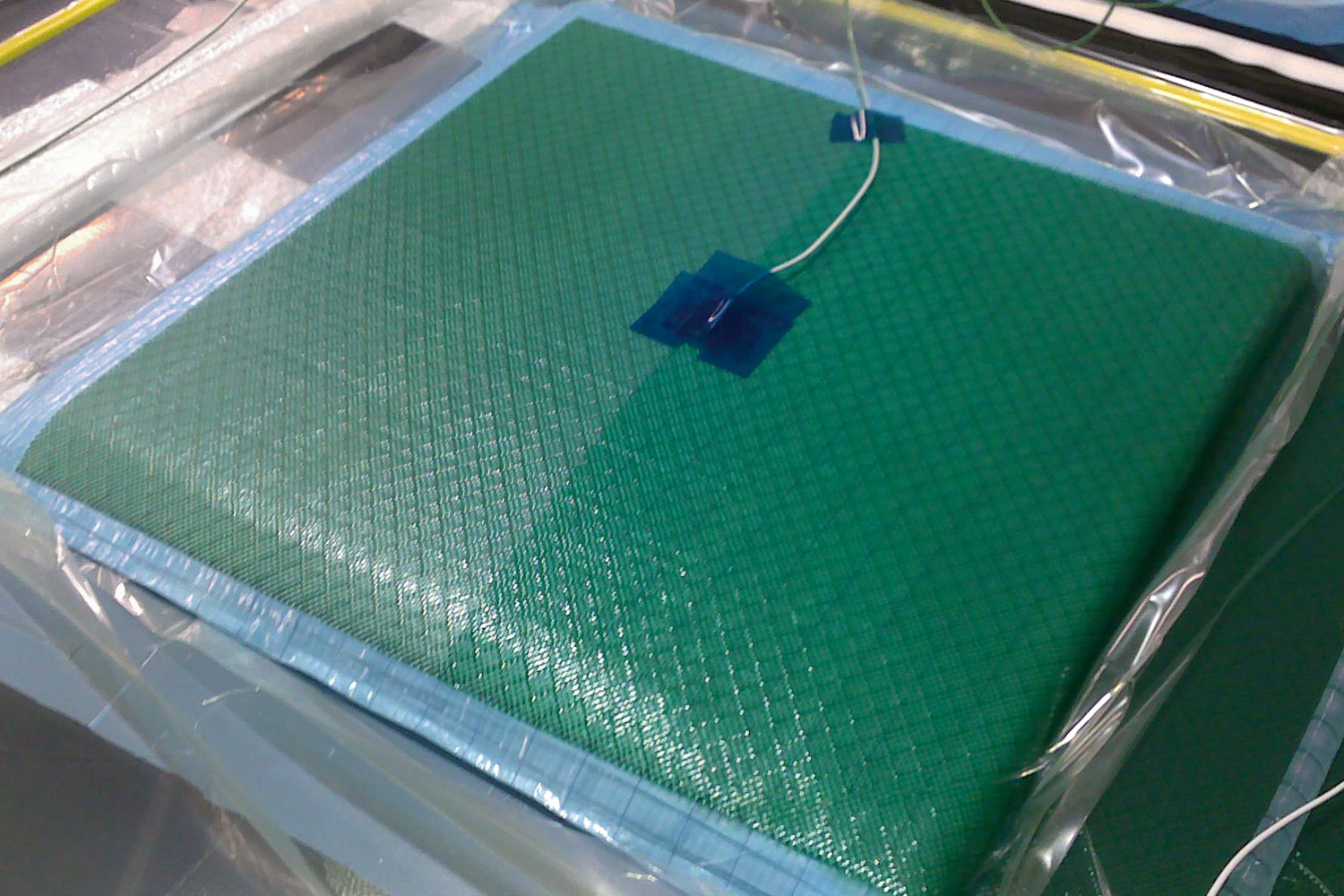

Throughout the whole infusion process, the carrier matrix is continuously kept under vacuum, thus avoiding enrichment with gases. The result is a significant increase of the product quality and no costs for refinishing. Additional post-curing times are also eliminated, and support productivity by a multitude.

|

|

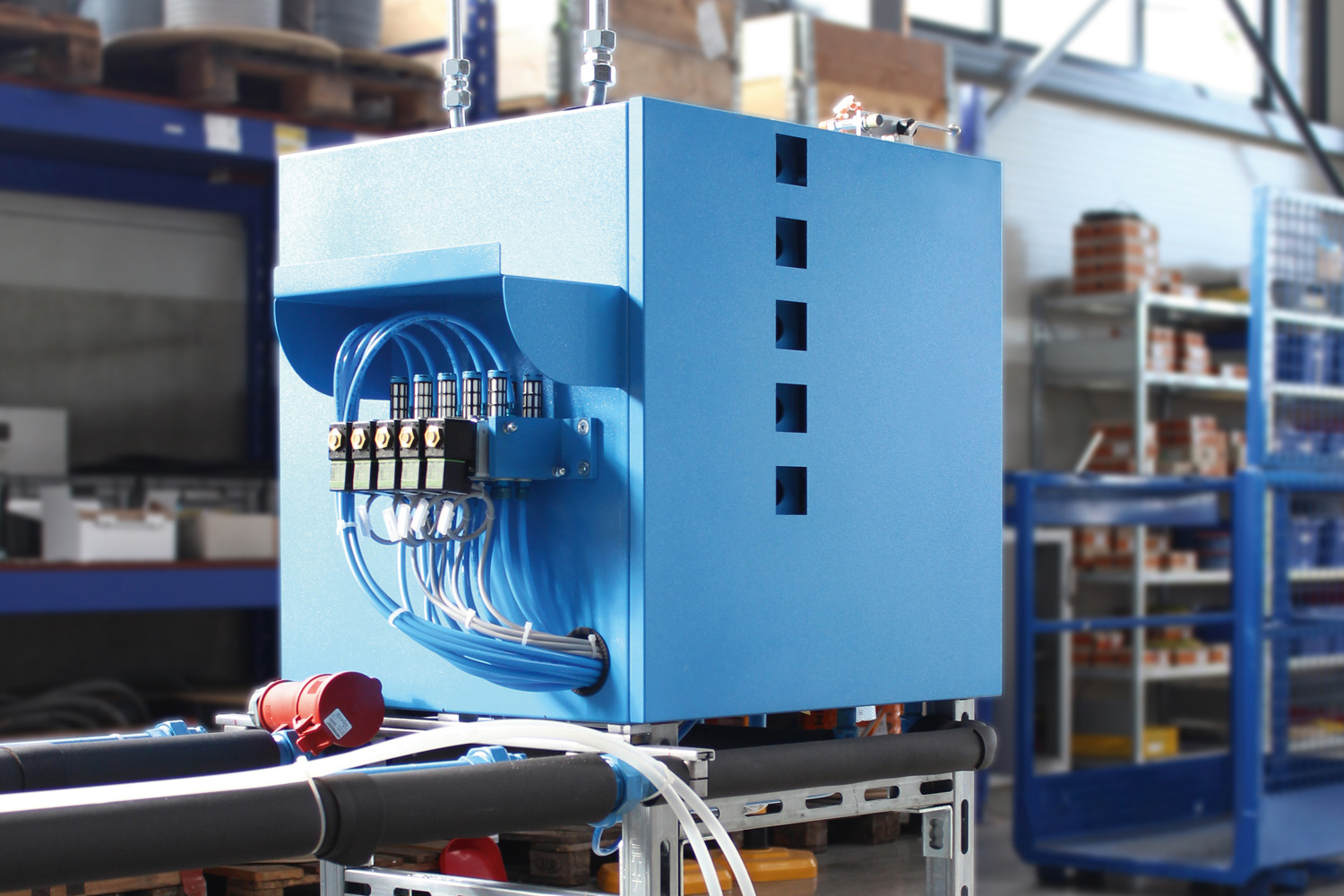

Intelligent Infusion |

The filling and mixing station (INFUCUBE) contains a softbag to control the cast resin refill process as required. This softbag is refilled automatically depending on the quantity consumed. So, there is just a minimum amount of remaining reactive material available at the end of the infusion process. Contaminated parts such as hoses, softbag and static mixer are very low-priced one-way resp. process-dependent consumables.

|

|

Constantly High Quality |

The HEDRICH VIA line provides a system to measure the residual moisture of fibre and core components, dry them under vacuum until a freely defined residual moisture degree is reached and then infuse the component automatically. This fully automatic process saves time, energy, man-power and grants reproducibility of highest quality requirements.

|

|

Maximum Stability |

Advantages of vacuum infusion equipment

Advantages of vacuum infusion equipment

• Quality improvement by less air accumulation

• Shorter mould occupation times and thus increase of production by abt. 10%

• Elimination of additional post-curing times

• Minimization of cast resin disposal costs

• Less material consumption by lower safety margins

• Separate degassing of resin and hardener for quality improvement

• Casting quantities up to 60 kg/min

• Technology for infusion also applicable for the pressure gelation technology

Applications

Applications

• Automotive

• Aerospace industry

• Boat building

• Strukture parts

• Composite components