Equipment for the Automatic Pressure Gelation (APG)

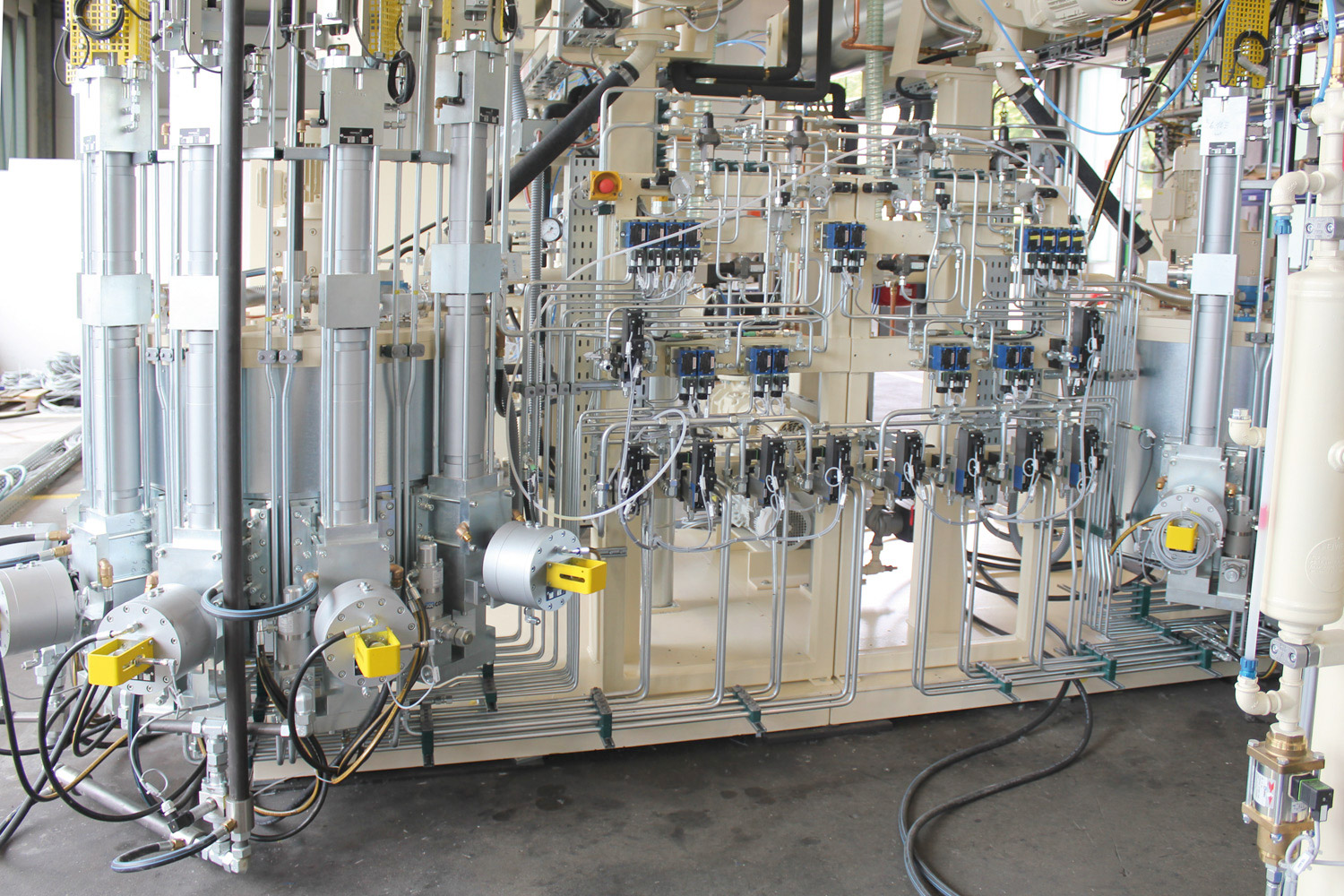

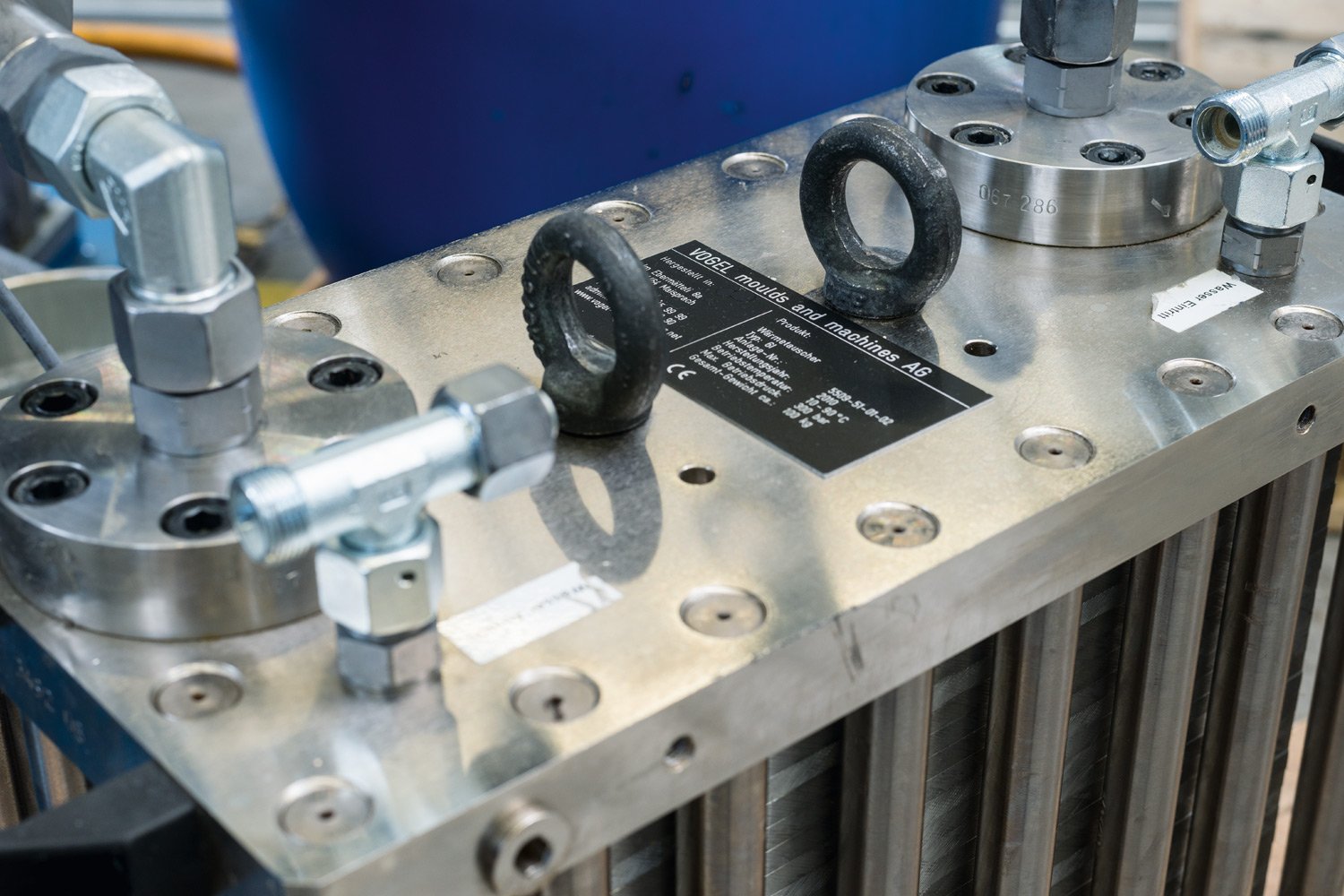

Besides vacuum casting, HEDRICH also manufactures equipment for the automatic pressure gelation (APG). This process has proven its excellence especially for components with large lot sizes, such as insulators, switch gear parts or instrument transformers. The moulds are pressure tight and fixed in a clamping unit. A batchwise and continuous process is possible. Casting is done mainly under atmospheric pressure. Optionally, pressure gelation is also possible under vacuum or with SF6 gas.

|

|

Fast and Continuous |

The OTF on-the-fly degasser achieves a very fast homogenization and degassing of epoxy resin and fillers after one single pass through. Short degassing and mixing time within a few minutes due to high shear forces between the stirring combs as well as degassing in thin layers. The degassing quality can be observed and inspected at any time through sight glasses in the OTF as well as in the buffer vessel.

|

|

Powerful and Precise |

The new generation of HEDRICH high-pressure dosing pumps Gen2 allows the processing of yet unreached filler portions in the cast resin matrix. The hydraulic drive already provides a linear movement as the pump itself, thus excluding the risk of inaccuracies. The extremely wear-resistant design ensures very long service lives.

|

|

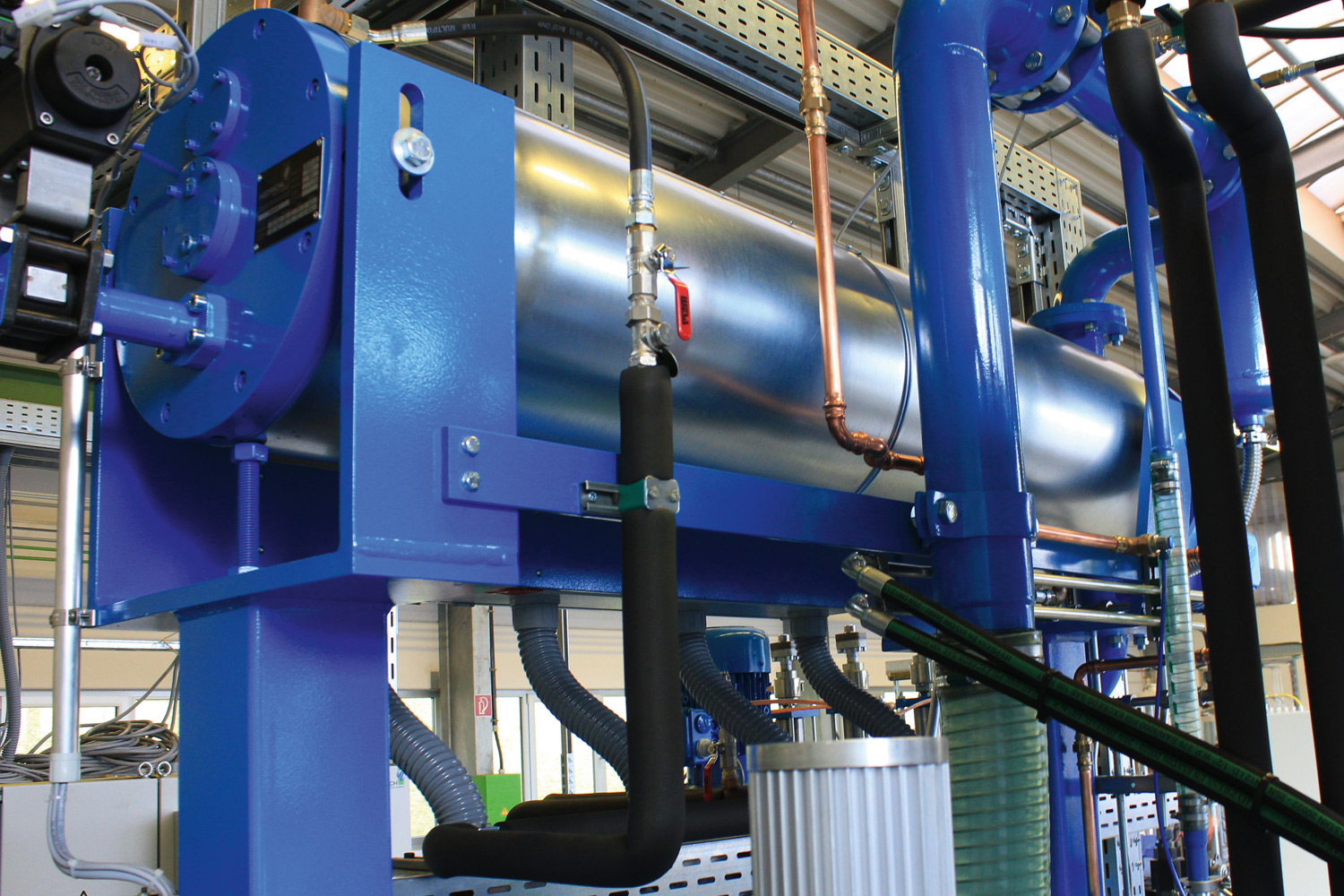

UFC – The Productive Turbo |

The patented HEDRICH UFC technologyTM allows to achieve very short gelation times. The cast resin compound is heated up by the HEDRICH developed UFC (Ultra Fast Compound) heater immediately before entering the moulds. So, we can grant a shortening of the gelation time with highest quality and resulting improved productivity of each clamping unit up to 50%.

|

|

Fully Automatic Production |

The robot is provided with a multifunction gripper arm to take over the complete process from loading and unloading of the mould as well as cleaning after demoulding and preparation for the next casting cycle. One robot can be used to operate several clamping units.

Advantages of APG vacuum pressure gelation equipment

Advantages of APG vacuum pressure gelation equipment

• Fully automatic vacuum pressure gelation production line for electric drives

• Patented fully automatic APG production with integrated screen processing

• Multi-injection process for the casting of components with large part weights

• Inline dosing supervision according to the highly precise Coriolis measuring principle

• PreCHECKTM filling and pressure test of the dosing pumps already before casting

• Material flow rate up to 10 t/day

• Connecting possibilities of up to 20 clamping units to one preparation system

• Patented casting process with subsequent pressure gelation tunnel oven system

• UFC technology to reduce cycle times and increase quality

Applications

Applications

• Current and voltage transformers

• Stators and rotors of high-capacity motors

• Medium voltage bushings

• Insulators